Page 57 - Advances in Textile Biotechnology

P. 57

36 Advances in textile biotechnology

2.3 Mass transfer limitations in textiles

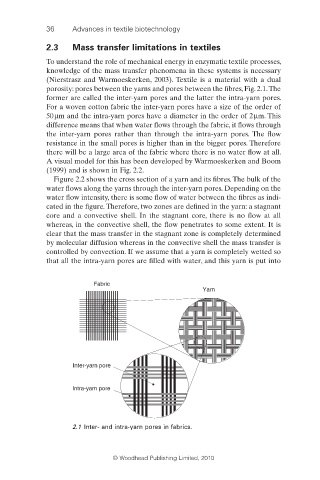

To understand the role of mechanical energy in enzymatic textile processes,

knowledge of the mass transfer phenomena in these systems is necessary

(Nierstrasz and Warmoeskerken, 2003). Textile is a material with a dual

porosity: pores between the yarns and pores between the fibres, Fig. 2.1. The

former are called the inter-yarn pores and the latter the intra-yarn pores.

For a woven cotton fabric the inter-yarn pores have a size of the order of

50 μm and the intra-yarn pores have a diameter in the order of 2 μm. This

difference means that when water flows through the fabric, it fl ows through

the inter-yarn pores rather than through the intra-yarn pores. The fl ow

resistance in the small pores is higher than in the bigger pores. Therefore

there will be a large area of the fabric where there is no water flow at all.

A visual model for this has been developed by Warmoeskerken and Boom

(1999) and is shown in Fig. 2.2.

Figure 2.2 shows the cross section of a yarn and its fibres. The bulk of the

water flows along the yarns through the inter-yarn pores. Depending on the

water fl ow intensity, there is some fl ow of water between the fi bres as indi-

cated in the figure. Therefore, two zones are defined in the yarn: a stagnant

core and a convective shell. In the stagnant core, there is no flow at all

whereas, in the convective shell, the flow penetrates to some extent. It is

clear that the mass transfer in the stagnant zone is completely determined

by molecular diffusion whereas in the convective shell the mass transfer is

controlled by convection. If we assume that a yarn is completely wetted so

that all the intra-yarn pores are filled with water, and this yarn is put into

Fabric

Yarn

Inter-yarn pore

Intra-yarn pore

2.1 Inter- and intra-yarn pores in fabrics.

© Woodhead Publishing Limited, 2010