Page 274 - Aeronautical Engineer Data Book

P. 274

220 Aeronautical Engineer’s Data Book

?

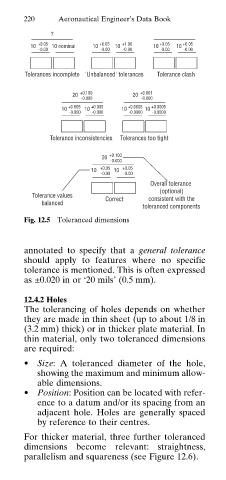

10 +0.05 10 nominal 10 +0.05 10 +1.00 10 +0.05 10 +0.05

-0.00 -0.00 -0.00 -0.00 -0.00

Tolerances incomplete 'Unbalanced' tolerances Tolerance clash

20 +0.100

20 +0.001

-0.000

-0.000

+0.005 +0.005 +0.0005 +0.0005

10 10 10 10

-0.000 -0.000 -0.0000 -0.0000

Tolerance inconsistencies Tolerances too tight

20 +0.100

-0.000

10 +0.05 10 +0.05

-0.00 -0.00

Overall tolerance

(optional)

Tolerance values

Correct consistent with the

balanced

toleranced components

Fig. 12.5 Toleranced dimensions

annotated to specify that a general tolerance

should apply to features where no specific

tolerance is mentioned. This is often expressed

as ±0.020 in or ‘20 mils’ (0.5 mm).

12.4.2 Holes

The tolerancing of holes depends on whether

they are made in thin sheet (up to about 1/8 in

(3.2 mm) thick) or in thicker plate material. In

thin material, only two toleranced dimensions

are required:

• Size: A toleranced diameter of the hole,

showing the maximum and minimum allow

able dimensions.

• Position: Position can be located with refer

ence to a datum and/or its spacing from an

adjacent hole. Holes are generally spaced

by reference to their centres.

For thicker material, three further toleranced

dimensions become relevant: straightness,

parallelism and squareness (see Figure 12.6).