Page 279 - Aeronautical Engineer Data Book

P. 279

Basic mechanical design 225

Upper deviation

(hole)

Lower deviation (hole) Lower deviation (shaft)

Hole

Upper deviation

(shaft)

Basic size Shaft Basic size Zero line

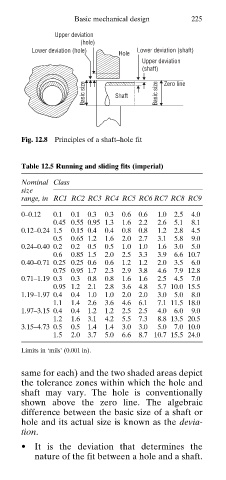

Fig. 12.8 Principles of a shaft–hole fit

Table 12.5 Running and sliding fits (imperial)

Nominal Class

size

range, in RC1 RC2 RC3 RC4 RC5 RC6 RC7 RC8 RC9

0–0.12 0.1 0.1 0.3 0.3 0.6 0.6 1.0 2.5 4.0

0.45 0.55 0.95 1.3 1.6 2.2 2.6 5.1 8.1

0.12–0.24 1.5 0.15 0.4 0.4 0.8 0.8 1.2 2.8 4.5

0.5 0.65 1.2 1.6 2.0 2.7 3.1 5.8 9.0

0.24–0.40 0.2 0.2 0.5 0.5 1.0 1.0 1.6 3.0 5.0

0.6 0.85 1.5 2.0 2.5 3.3 3.9 6.6 10.7

0.40–0.71 0.25 0.25 0.6 0.6 1.2 1.2 2.0 3.5 6.0

0.75 0.95 1.7 2.3 2.9 3.8 4.6 7.9 12.8

0.71–1.19 0.3 0.3 0.8 0.8 1.6 1.6 2.5 4.5 7.0

0.95 1.2 2.1 2.8 3.6 4.8 5.7 10.0 15.5

1.19–1.97 0.4 0.4 1.0 1.0 2.0 2.0 3.0 5.0 8.0

1.1 1.4 2.6 3.6 4.6 6.1 7.1 11.5 18.0

1.97–3.15 0.4 0.4 1.2 1.2 2.5 2.5 4.0 6.0 9.0

1.2 1.6 3.1 4.2 5.5 7.3 8.8 13.5 20.5

3.15–4.73 0.5 0.5 1.4 1.4 3.0 3.0 5.0 7.0 10.0

1.5 2.0 3.7 5.0 6.6 8.7 10.7 15.5 24.0

Limits in ‘mils’ (0.001 in).

same for each) and the two shaded areas depict

the tolerance zones within which the hole and

shaft may vary. The hole is conventionally

shown above the zero line. The algebraic

difference between the basic size of a shaft or

hole and its actual size is known as the devia

tion.

• It is the deviation that determines the

nature of the fit between a hole and a shaft.