Page 281 - Aeronautical Engineer Data Book

P. 281

Basic mechanical design 227

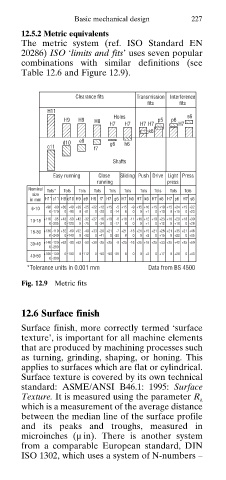

12.5.2 Metric equivalents

The metric system (ref. ISO Standard EN

20286) ISO ‘limits and fits’ uses seven popular

combinations with similar definitions (see

Table 12.6 and Figure 12.9).

Clearance fits Transmission Interference

fits fits

H11

Holes s6

H9 H9 H8 p5 p6

H7 H7 H7 H7 H7

k6

d10 e9 g6 h6

c11 f7

Shafts

Easy running Close Sliding Push Drive Light Press

running press

Nominal

Tols* Tols Tols Tols Tols Tols Tols Tols Tols Tols

size

in mm H11 c11 H9 d10 H9 e9 H8 f7 H7 g6 H7 h6 H7 k6 H7 n6 H7 p6 H7 s6

+90 -80 +36 -40 +36 -25 +22 -12 +15 -5 +15 -9 +15 +10 +15 +19 +15 +24 +15 +32

6-10

0 -170 0 -98 0 -61 0 -28 0 -14 0 0 0 +1 0 +10 0 +15 0 +23

10-18 +110 -95 +43 -50 +43 -32 +27 -16 +18 -6 +18 -11 +18 +12 +18 +23 +18 +29 +18 +39

0 -205 0 -120 0 -75 0 -34 0 -17 0 0 0 +1 0 +12 0 +18 0 +28

18-30 +130 -110 +52 -69 +52 -40 +33 -20 +21 -7 +21 -13 +21 +15 +21 +28 +21 +35 +21 +48

0 -240 0 -149 0 -92 0 -41 0 -20 0 0 0 +2 0 +15 0 +22 0 +35

30-40 +140 -120 +62 -80 +62 -50 +39 -25 +25 -9 +25 -16 +25 +18 +25 +33 +25 +42 +25 +59

0 -280

+160 -130 0 -180 0 -112 0 -50 -50 -25 0 0 0 +2 0 +17 0 +26 0 +43

40-50

0 -290

*Tolerance units in 0.001 mm Data from BS 4500

Fig. 12.9 Metric fits

12.6 Surface finish

Surface finish, more correctly termed ‘surface

texture’, is important for all machine elements

that are produced by machining processes such

as turning, grinding, shaping, or honing. This

applies to surfaces which are flat or cylindrical.

Surface texture is covered by its own technical

standard: ASME/ANSI B46.1: 1995: Surface

Texture. It is measured using the parameter R a

which is a measurement of the average distance

between the median line of the surface profile

and its peaks and troughs, measured in

microinches (µ in). There is another system

from a comparable European standard, DIN

ISO 1302, which uses a system of N-numbers –