Page 100 - Air Pollution Control Engineering

P. 100

02_chap_wang.qxd 05/05/2004 12:40 pm Page 80

80 Lawrence K. Wang et al.

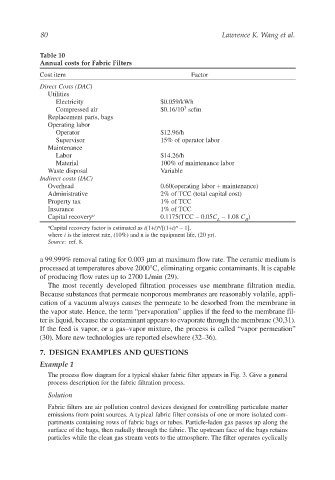

Table 10

Annual costs for Fabric Filters

Cost item Factor

Direct Costs (DAC)

Utilities

Electricity $0.059/kWh

3

Compressed air $0.16/10 scfm

Replacement parts, bags

Operating labor

Operator $12.96/h

Supervisor 15% of operator labor

Maintenance

Labor $14.26/h

Material 100% of maintenance labor

Waste disposal Variable

Indirect costs (IAC)

Overhead 0.60(operating labor + maintenance)

Administrative 2% of TCC (total capital cost)

Property tax 1% of TCC

Insurance 1% of TCC

Capital recovery a 0.1175(TCC − 0.05C − 1.08 C )

L B

n

a Capital recovery factor is estimated as i(1+i) /[(1+i) − 1],

n

where i is the interest rate, (10%) and n is the equipment life, (20 yr).

Source: ref. 8.

a 99.999% removal rating for 0.003 µm at maximum flow rate. The ceramic medium is

processed at temperatures above 2000°C, eliminating organic contaminants. It is capable

of producing flow rates up to 2700 L/min (29).

The most recently developed filtration processes use membrane filtration media.

Because substances that permeate nonporous membranes are reasonably volatile, appli-

cation of a vacuum always causes the permeate to be desorbed from the membrane in

the vapor state. Hence, the term “pervaporation” applies if the feed to the membrane fil-

ter is liquid, because the contaminant appears to evaporate through the membrane (30,31).

If the feed is vapor, or a gas–vapor mixture, the process is called “vapor permeation”

(30). More new technologies are reported elsewhere (32–36).

7. DESIGN EXAMPLES AND QUESTIONS

Example 1

The process flow diagram for a typical shaker fabric filter appears in Fig. 3. Give a general

process description for the fabric filtration process.

Solution

Fabric filters are air pollution control devices designed for controlling particulate matter

emissions from point sources. A typical fabric filter consists of one or more isolated com-

partments containing rows of fabric bags or tubes. Particle-laden gas passes up along the

surface of the bags, then radially through the fabric. The upstream face of the bags retains

particles while the clean gas stream vents to the atmosphere. The filter operates cyclically