Page 99 - Air Pollution Control Engineering

P. 99

02_chap_wang.qxd 05/05/2004 12:40 pm Page 79

Fabric Filtration 79

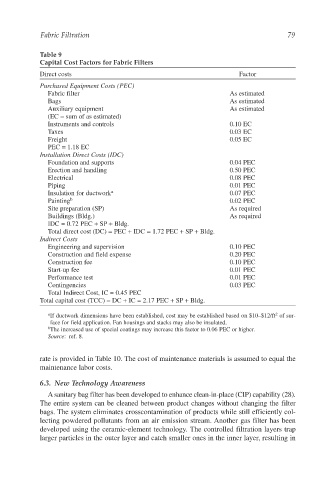

Table 9

Capital Cost Factors for Fabric Filters

Direct costs Factor

Purchased Equipment Costs (PEC)

Fabric filter As estimated

Bags As estimated

Auxiliary equipment As estimated

(EC = sum of as estimated)

Instruments and controls 0.10 EC

Taxes 0.03 EC

Freight 0.05 EC

PEC = 1.18 EC

Installation Direct Costs (IDC)

Foundation and supports 0.04 PEC

Erection and handling 0.50 PEC

Electrical 0.08 PEC

Piping 0.01 PEC

Insulation for ductwork a 0.07 PEC

Painting b 0.02 PEC

Site preparation (SP) As required

Buildings (Bldg.) As required

IDC = 0.72 PEC + SP + Bldg.

Total direct cost (DC) = PEC + IDC = 1.72 PEC + SP + Bldg.

Indirect Costs

Engineering and supervision 0.10 PEC

Construction and field expense 0.20 PEC

Construction fee 0.10 PEC

Start-up fee 0.01 PEC

Performance test 0.01 PEC

Contingencies 0.03 PEC

Total Indirect Cost, IC = 0.45 PEC

Total capital cost (TCC) = DC + IC = 2.17 PEC + SP + Bldg.

2

a If ductwork dimensions have been established, cost may be established based on $10–$12/ft of sur-

face for field application. Fan housings and stacks may also be insulated.

b The increased use of special coatings may increase this factor to 0.06 PEC or higher.

Source: ref. 8.

rate is provided in Table 10. The cost of maintenance materials is assumed to equal the

maintenance labor costs.

6.3. New Technology Awareness

Asanitary bag filter has been developed to enhance clean-in-place (CIP) capability (28).

The entire system can be cleaned between product changes without changing the filter

bags. The system eliminates crosscontamination of products while still efficiently col-

lecting powdered pollutants from an air emission stream. Another gas filter has been

developed using the ceramic-element technology. The controlled filtration layers trap

larger particles in the outer layer and catch smaller ones in the inner layer, resulting in