Page 245 - Air Pollution Control Engineering

P. 245

05_chap_wang.qxd 05/05/2004 3:46 pm Page 224

224 Lawrence K. Wang et al.

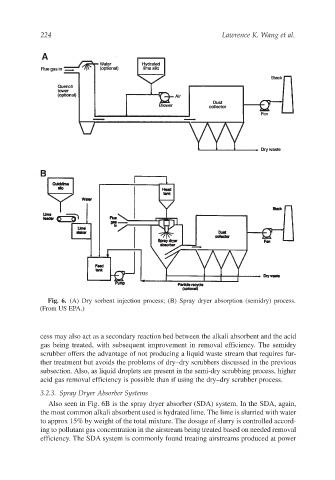

Fig. 6. (A) Dry sorbent injection process; (B) Spray dryer absorption (semidry) process.

(From US EPA.)

cess may also act as a secondary reaction bed between the alkali absorbent and the acid

gas being treated, with subsequent improvement in removal efficiency. The semidry

scrubber offers the advantage of not producing a liquid waste stream that requires fur-

ther treatment but avoids the problems of dry–dry scrubbers discussed in the previous

subsection. Also, as liquid droplets are present in the semi-dry scrubbing process, higher

acid gas removal efficiency is possible than if using the dry–dry scrubber process.

3.2.3. Spray Dryer Absorber Systems

Also seen in Fig. 6B is the spray dryer absorber (SDA) system. In the SDA, again,

the most common alkali absorbent used is hydrated lime. The lime is slurried with water

to approx 15% by weight of the total mixture. The dosage of slurry is controlled accord-

ing to pollutant gas concentration in the airstream being treated based on needed removal

efficiency. The SDA system is commonly found treating airstreams produced at power