Page 284 - Air Pollution Control Engineering

P. 284

05_chap_wang.qxd 05/05/2004 3:51 pm Page 263

Wet and Dry Scrubbing 263

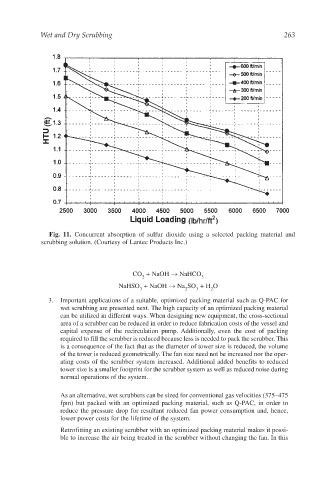

Fig. 11. Concurrent absorption of sulfur dioxide using a selected packing material and

scrubbing solution. (Courtesy of Lantec Products Inc.)

CO + NaOH → NaHCO

2 3

NaHSO + NaOH → Na SO + H O

3 2 3 2

3. Important applications of a suitable, optimized packing material such as Q-PAC for

wet scrubbing are presented next. The high capacity of an optimized packing material

can be utilized in different ways. When designing new equipment, the cross-sectional

area of a scrubber can be reduced in order to reduce fabrication costs of the vessel and

capital expense of the recirculation pump. Additionally, even the cost of packing

required to fill the scrubber is reduced because less is needed to pack the scrubber. This

is a consequence of the fact that as the diameter of tower size is reduced, the volume

of the tower is reduced geometrically. The fan size need not be increased nor the oper-

ating costs of the scrubber system increased. Additional added benefits to reduced

tower size is a smaller footprint for the scrubber system as well as reduced noise during

normal operations of the system.

As an alternative, wet scrubbers can be sized for conventional gas velocities (375–475

fpm) but packed with an optimized packing material, such as Q-PAC, in order to

reduce the pressure drop for resultant reduced fan power consumption and, hence,

lower power costs for the lifetime of the system.

Retrofitting an existing scrubber with an optimized packing material makes it possi-

ble to increase the air being treated in the scrubber without changing the fan. In this