Page 310 - Air Pollution Control Engineering

P. 310

05_chap_wang.qxd 05/05/2004 3:51 pm Page 289

Wet and Dry Scrubbing 289

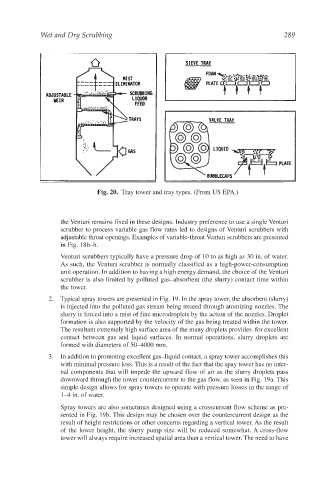

Fig. 20. Tray tower and tray types. (From US EPA.)

the Venturi remains fixed in these designs. Industry preference to use a single Venturi

scrubber to process variable gas flow rates led to designs of Venturi scrubbers with

adjustable throat openings. Examples of variable-throat Venturi scrubbers are presented

in Fig. 18b–h.

Venturi scrubbers typically have a pressure drop of 10 to as high as 30 in. of water.

As such, the Venturi scrubber is normally classified as a high-power-consumption

unit operation. In addition to having a high energy demand, the choice of the Venturi

scrubber is also limited by polluted gas–absorbent (the slurry) contact time within

the tower.

2. Typical spray towers are presented in Fig. 19. In the spray tower, the absorbent (slurry)

is injected into the polluted gas stream being treated through atomizing nozzles. The

slurry is forced into a mist of fine microdroplets by the action of the nozzles. Droplet

formation is also supported by the velocity of the gas being treated within the tower.

The resultant extremely high surface area of the many droplets provides. for excellent

contact between gas and liquid surfaces. In normal operations, slurry droplets are

formed with diameters of 50–4000 mm.

3. In addition to promoting excellent gas–liquid contact, a spray tower accomplishes this

with minimal pressure loss. This is a result of the fact that the spay tower has no inter-

nal components that will impede the upward flow of air as the slurry droplets pass

downward through the tower countercurrent to the gas flow, as seen in Fig. 19a. This

simple design allows for spray towers to operate with pressure losses in the range of

1–4 in. of water.

Spray towers are also sometimes designed using a crosscurrent flow scheme as pre-

sented in Fig. 19b. This design may be chosen over the countercurrent design as the

result of height restrictions or other concerns regarding a vertical tower. As the result

of the lower height, the slurry pump size will be reduced somewhat. A cross-flow

tower will always require increased spatial area than a vertical tower. The need to have