Page 359 - Air Pollution Control Engineering

P. 359

07_Chap_Wang.qxd 05/05/2004 4:19 pm Page 336

336 Lawrence K. Wang et al.

this handbook. Selecting thermal treatment equipment to destroy organic vapors is a

challenge. The large number of treatment operations and the myriad of possible vent

stream conditions create a very large set of choices to be evaluated, each of which has

benefits and disadvantages. Martin et al. (17) state that it is difficult to effectively cap-

ture and treat acid gas products from a flare, because a flare is designed to exhaust

directly to atmosphere. An enclosed flare is basically an open flare installed at the

bottom of a refractory-lined stack. Moretti and Mukhopadhyay (18) compare the flare

process with other VOC control technologies, such as catalytic oxidation, condensation,

adsorption, absorption, biofiltration, membrane separation, ultraviolet (UV) oxidation,

and heaters.

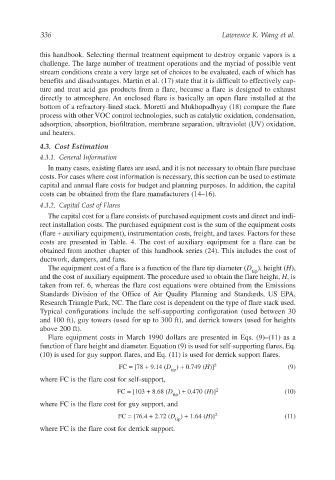

4.3. Cost Estimation

4.3.1. General Information

In many cases, existing flares are used, and it is not necessary to obtain flare purchase

costs. For cases where cost information is necessary, this section can be used to estimate

capital and annual flare costs for budget and planning purposes. In addition, the capital

costs can be obtained from the flare manufacturers (14–16).

4.3.2. Capital Cost of Flares

The capital cost for a flare consists of purchased equipment costs and direct and indi-

rect installation costs. The purchased equipment cost is the sum of the equipment costs

(flare + auxiliary equipment), instrumentation costs, freight, and taxes. Factors for these

costs are presented in Table. 4. The cost of auxiliary equipment for a flare can be

obtained from another chapter of this handbook series (24). This includes the cost of

ductwork, dampers, and fans.

The equipment cost of a flare is a function of the flare tip diameter (D ), height (H),

tip

and the cost of auxiliary equipment. The procedure used to obtain the flare height, H, is

taken from ref. 6, whereas the flare cost equations were obtained from the Emissions

Standards Division of the Office of Air Quality Planning and Standards, US EPA,

Research Triangle Park, NC. The flare cost is dependent on the type of flare stack used.

Typical configurations include the self-supporting configuration (used between 30

and 100 ft), guy towers (used for up to 300 ft), and derrick towers (used for heights

above 200 ft).

Flare equipment costs in March 1990 dollars are presented in Eqs. (9)–(11) as a

function of flare height and diameter. Equation (9) is used for self-supporting flares, Eq.

(10) is used for guy support flares, and Eq. (11) is used for derrick support flares.

FC = [78 + 9.14 (D ) + 0.749 (H)] 2 (9)

tip

where FC is the flare cost for self-support,

FC = [103 + 8.68 (D ) + 0.470 (H)] 2 (10)

tip

where FC is the flare cost for guy support, and

FC = [76.4 + 2.72 (D ) + 1.64 (H)] 2 (11)

tip

where FC is the flare cost for derrick support.