Page 354 - Air Pollution Control Engineering

P. 354

07_Chap_Wang.qxd 05/05/2004 4:19 pm Page 332

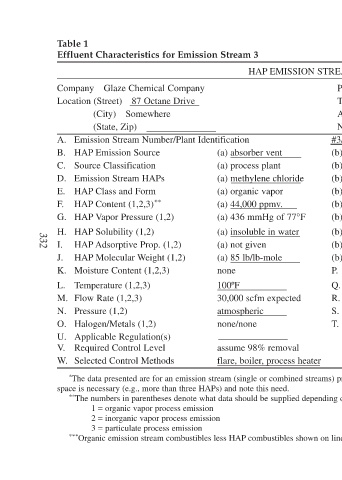

EMISSION STREAM DATA FORM * Mr. John Leake Plant contact (999) 555–5024 Telephone No. Mr. Efrem Johnson Agency contact 7 No. of Emission Streams Under Review #3/Acetaldehyde Manufacturing Absorber Vent (c) (b) (c) (b) (c) (b) (c) (b) (c) (b) (c) (b) (c) (b) (c) (b) (c) (b) 17.8% vol CH 4 Organic Content (1)*** P. 180 Btu/scf/ none Content (1) Heat/O 2 Q.

HAP (a) absorber vent (a) process plant (a) methylene chloride (a) organic vapor (a) 44,000 ppmv. (a) 436 mmHg of 77°F (a) insoluble in water (a) not given (a) 85 lb/lb-mole none 100ºF 30,000 scfm expected atmospheric none/none assume 98% removal flare, boiler, process heater ** The numbers in parentheses denote what data should be supplied depending on

Effluent Characteristics for Emission Stream 3

Glaze Chemical Company 87 Octane Drive Somewhere (State, Zip) Emission Stream Number/Plant Identification Emission Source Source Classification Emission Stream HAPs Class and Form Content (1,2,3) ** Vapor Pressure (1,2) Solubility (1,2) HAP Adsorptive Prop. (1,2) Molecular Weight (1,2) Moisture Content (1,2,3) Halogen/Metals (1,2) Applicable Regulation(s) Required

Table 1 Company Location (Street) (City) A. HAP B. C. D. HAP E. HAP F. HAP G. HAP H. I. HAP J. K. Temperature (1,2,3) L. Flow Rate (1,2,3) M. Pressure (1,2) N. O. U. V. W. = 1 = 2 = 3

332