Page 352 - Air Pollution Control Engineering

P. 352

07_Chap_Wang.qxd 05/05/2004 4:19 pm Page 330

330 Lawrence K. Wang et al.

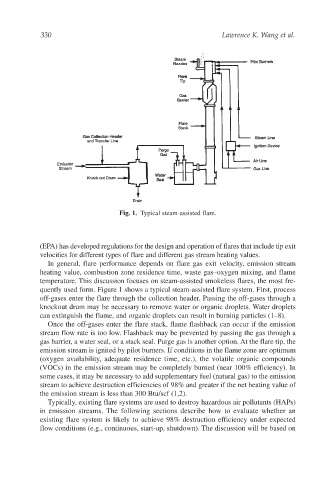

Fig. 1. Typical steam-assisted flare.

(EPA) has developed regulations for the design and operation of flares that include tip exit

velocities for different types of flare and different gas stream heating values.

In general, flare performance depends on flare gas exit velocity, emission stream

heating value, combustion zone residence time, waste gas–oxygen mixing, and flame

temperature. This discussion focuses on steam-assisted smokeless flares, the most fre-

quently used form. Figure 1 shows a typical steam-assisted flare system. First, process

off-gases enter the flare through the collection header. Passing the off-gases through a

knockout drum may be necessary to remove water or organic droplets. Water droplets

can extinguish the flame, and organic droplets can result in burning particles (1–8).

Once the off-gases enter the flare stack, flame flashback can occur if the emission

stream flow rate is too low. Flashback may be prevented by passing the gas through a

gas barrier, a water seal, or a stack seal. Purge gas is another option. At the flare tip, the

emission stream is ignited by pilot burners. If conditions in the flame zone are optimum

(oxygen availability, adequate residence time, etc.), the volatile organic compounds

(VOCs) in the emission stream may be completely burned (near 100% efficiency). In

some cases, it may be necessary to add supplementary fuel (natural gas) to the emission

stream to achieve destruction efficiencies of 98% and greater if the net heating value of

the emission stream is less than 300 Btu/scf (1,2).

Typically, existing flare systems are used to destroy hazardous air pollutants (HAPs)

in emission streams. The following sections describe how to evaluate whether an

existing flare system is likely to achieve 98% destruction efficiency under expected

flow conditions (e.g., continuous, start-up, shutdown). The discussion will be based on