Page 399 - Air Pollution Control Engineering

P. 399

09_chap_wang.qxd 05/05/2004 5:01 pm Page 373

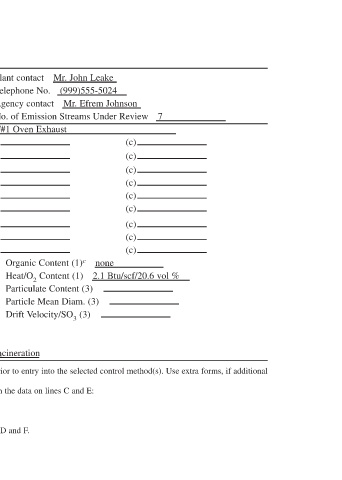

7 (c) (c) (c) (c) (c) (c) (c) (c) (c) 2.1 Btu/scf/20.6 vol %

Mr. John Leake (999)555-5024 Mr. Efrem Johnson No. of Emission Streams Under Review none Content (1) Particle Mean Diam. (3) (3)

Plant contact Telephone No. Agency contact #2/#1 Oven Exhaust (b) (b) (b) (b) (b) (b) (b) (b) (b) Organic Content (1) c P. Heat/O 2 Q. Particulate Content (3) R. S. Drift Velocity/SO 3 T. a The data presented are for an emission stream (single or combined streams) prior to entry into the selected control method(s). Use extra forms, if additional

metal coating oven process point toluene organic vapor 550 ppmv 28.4 mm Hg at 77ºF insoluble in water provided 92 lb/lb-mole 20,000 scfm (max) Assume 95% removal Thermal incineration, catalytic incineration b The numbers in parentheses denote what data should be supplied depending on the data on lines C and E: combustibles shown on lines D and F.

Effluent Characteristics for emission stream 2 a

(a) (a) (a) (a) (a) (a) (a) (a) (a) 2% volume 120ºF atmospheric none/none

Glaze Chemical Company 87 Octane Drive Somewhere (State, Zip) Emission Stream Number/Plant Identification Emission Source Source Classification Emission Stream HAPs Class and Form Content (1,2,3) b Vapor Pressure (1,2) Solubility (1,2) HAP Adsorptive Prop. (1,2) Molecular Weight (1,2) Moisture Content (1,2,3) Halogen/Metals (1,2) Applicable Regulation(s) Required Co

Table 1 Company Location (Street) (City) A. HAP B. C. D. HAP E. HAP F. HAP G. HAP H. I. HAP J. K. Temperature (1,2,3) L. Flow Rate (1,2,3) M. Pressure (1,2) N. O. U. V. W. = 1 = 2 = 3

373