Page 467 - Air Pollution Control Engineering

P. 467

11_chap_wang.qxd 05/05/2004 5:19 pm Page 439

Gas-Phase Biofiltration 439

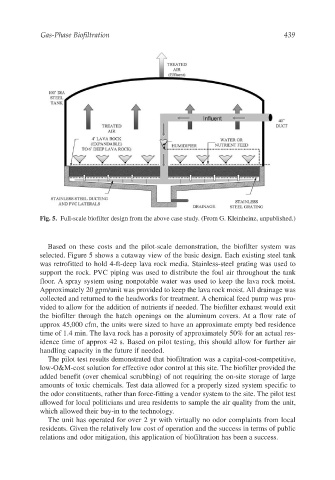

Fig. 5. Full-scale biofilter design from the above case study. (From G. Kleinheinz, unpublished.)

Based on these costs and the pilot-scale demonstration, the biofilter system was

selected. Figure 5 shows a cutaway view of the basic design. Each existing steel tank

was retrofitted to hold 4-ft-deep lava rock media. Stainless-steel grating was used to

support the rock. PVC piping was used to distribute the foul air throughout the tank

floor. A spray system using nonpotable water was used to keep the lava rock moist.

Approximately 20 gpm/unit was provided to keep the lava rock moist. All drainage was

collected and returned to the headworks for treatment. A chemical feed pump was pro-

vided to allow for the addition of nutrients if needed. The biofilter exhaust would exit

the biofilter through the hatch openings on the aluminum covers. At a flow rate of

approx 45,000 cfm, the units were sized to have an approximate empty bed residence

time of 1.4 min. The lava rock has a porosity of approximately 50% for an actual res-

idence time of approx 42 s. Based on pilot testing, this should allow for further air

handling capacity in the future if needed.

The pilot test results demonstrated that biofiltration was a capital-cost-competitive,

low-O&M-cost solution for effective odor control at this site. The biofilter provided the

added benefit (over chemical scrubbing) of not requiring the on-site storage of large

amounts of toxic chemicals. Test data allowed for a properly sized system specific to

the odor constituents, rather than force-fitting a vendor system to the site. The pilot test

allowed for local politicians and area residents to sample the air quality from the unit,

which allowed their buy-in to the technology.

The unit has operated for over 2 yr with virtually no odor complaints from local

residents. Given the relatively low cost of operation and the success in terms of public

relations and odor mitigation, this application of biofiltration has been a success.