Page 144 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 144

118 5 Principles for Gas Separation

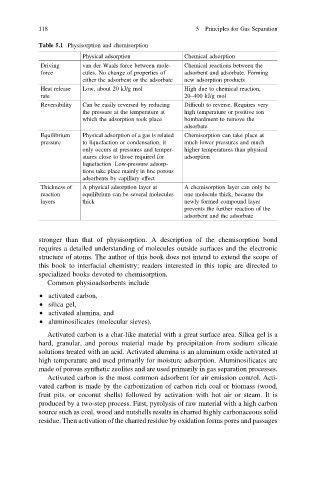

Table 5.1 Physisorption and chemisorption

Physical adsorption Chemical adsorption

Driving van der Waals force between mole- Chemical reactions between the

force cules. No change of properties of adsorbent and adsorbate. Forming

either the adsorbent or the adsorbate new adsorption products

Heat release Low, about 20 kJ/g mol High due to chemical reaction,

rate 20–400 kJ/g mol

Reversibility Can be easily reversed by reducing Difficult to reverse. Requires very

the pressure at the temperature at high temperature or positive ion

which the adsorption took place bombardment to remove the

adsorbate

Equilibrium Physical adsorption of a gas is related Chemisorption can take place at

pressure to liquefaction or condensation, it much lower pressures and much

only occurs at pressures and temper- higher temperatures than physical

atures close to those required for adsorption

liquefaction. Low-pressure adsorp-

tions take place mainly in fine porous

adsorbents by capillary effect

Thickness of A physical adsorption layer at A chemisorption layer can only be

reaction equilibrium can be several molecules one molecule thick, because the

layers thick newly formed compound layer

prevents the further reaction of the

adsorbent and the adsorbate

stronger than that of physisorption. A description of the chemisorption bond

requires a detailed understanding of molecules outside surfaces and the electronic

structure of atoms. The author of this book does not intend to extend the scope of

this book to interfacial chemistry; readers interested in this topic are directed to

specialized books devoted to chemisorption.

Common physioadsorbents include

• activated carbon,

• silica gel,

• activated alumina, and

• aluminosilicates (molecular sieves).

Activated carbon is a char-like material with a great surface area. Silica gel is a

hard, granular, and porous material made by precipitation from sodium silicate

solutions treated with an acid. Activated alumina is an aluminum oxide activated at

high temperature and used primarily for moisture adsorption. Aluminosilicates are

made of porous synthetic zeolites and are used primarily in gas separation processes.

Activated carbon is the most common adsorbent for air emission control. Acti-

vated carbon is made by the carbonization of carbon rich coal or biomass (wood,

fruit pits, or coconut shells) followed by activation with hot air or steam. It is

produced by a two-step process. First, pyrolysis of raw material with a high carbon

source such as coal, wood and nutshells results in charred highly carbonaceous solid

residue. Then activation of the charred residue by oxidation forms pores and passages