Page 324 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 324

10.6 Control of Volatile Organic Compounds 301

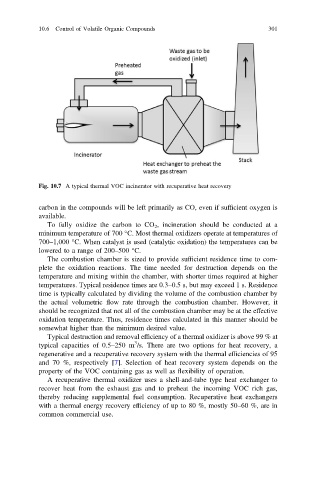

Fig. 10.7 A typical thermal VOC incinerator with recuperative heat recovery

carbon in the compounds will be left primarily as CO, even if sufficient oxygen is

available.

To fully oxidize the carbon to CO 2 , incineration should be conducted at a

minimum temperature of 700 °C. Most thermal oxidizers operate at temperatures of

700–1,000 °C. When catalyst is used (catalytic oxidation) the temperatures can be

lowered to a range of 200–500 °C.

The combustion chamber is sized to provide sufficient residence time to com-

plete the oxidation reactions. The time needed for destruction depends on the

temperature and mixing within the chamber, with shorter times required at higher

temperatures. Typical residence times are 0.3–0.5 s, but may exceed 1 s. Residence

time is typically calculated by dividing the volume of the combustion chamber by

the actual volumetric flow rate through the combustion chamber. However, it

should be recognized that not all of the combustion chamber may be at the effective

oxidation temperature. Thus, residence times calculated in this manner should be

somewhat higher than the minimum desired value.

Typical destruction and removal efficiency of a thermal oxidizer is above 99 % at

3

typical capacities of 0.5–250 m /s. There are two options for heat recovery, a

regenerative and a recuperative recovery system with the thermal efficiencies of 95

and 70 %, respectively [7]. Selection of heat recovery system depends on the

property of the VOC containing gas as well as flexibility of operation.

A recuperative thermal oxidizer uses a shell-and-tube type heat exchanger to

recover heat from the exhaust gas and to preheat the incoming VOC rich gas,

thereby reducing supplemental fuel consumption. Recuperative heat exchangers

with a thermal energy recovery efficiency of up to 80 %, mostly 50–60 %, are in

common commercial use.