Page 325 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 325

302 10 Post-combustion Air Emission Control

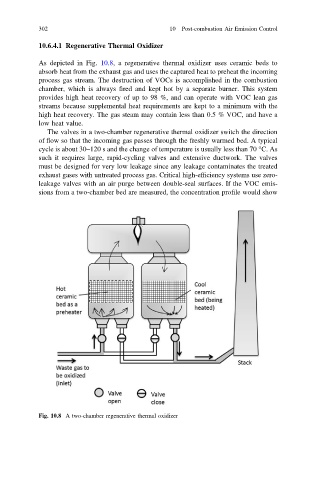

10.6.4.1 Regenerative Thermal Oxidizer

As depicted in Fig. 10.8, a regenerative thermal oxidizer uses ceramic beds to

absorb heat from the exhaust gas and uses the captured heat to preheat the incoming

process gas stream. The destruction of VOCs is accomplished in the combustion

chamber, which is always fired and kept hot by a separate burner. This system

provides high heat recovery of up to 98 %, and can operate with VOC lean gas

streams because supplemental heat requirements are kept to a minimum with the

high heat recovery. The gas steam may contain less than 0.5 % VOC, and have a

low heat value.

The valves in a two-chamber regenerative thermal oxidizer switch the direction

of flow so that the incoming gas passes through the freshly warmed bed. A typical

cycle is about 30–120 s and the change of temperature is usually less than 70 °C. As

such it requires large, rapid-cycling valves and extensive ductwork. The valves

must be designed for very low leakage since any leakage contaminates the treated

exhaust gases with untreated process gas. Critical high-efficiency systems use zero-

leakage valves with an air purge between double-seal surfaces. If the VOC emis-

sions from a two-chamber bed are measured, the concentration profile would show

Fig. 10.8 A two-chamber regenerative thermal oxidizer