Page 327 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 327

304 10 Post-combustion Air Emission Control

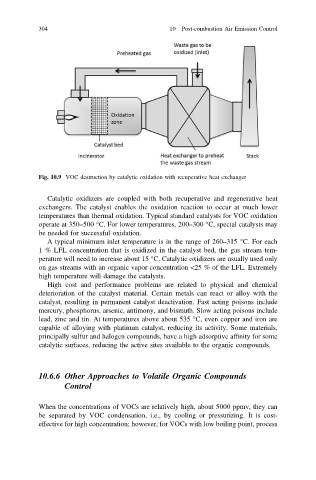

Fig. 10.9 VOC destruction by catalytic oxidation with recuperative heat exchanger

Catalytic oxidizers are coupled with both recuperative and regenerative heat

exchangers. The catalyst enables the oxidation reaction to occur at much lower

temperatures than thermal oxidation. Typical standard catalysts for VOC oxidation

operate at 350–500 °C. For lower temperatures, 200–300 °C, special catalysts may

be needed for successful oxidation.

A typical minimum inlet temperature is in the range of 260–315 °C. For each

1 % LFL concentration that is oxidized in the catalyst bed, the gas stream tem-

perature will need to increase about 15 °C. Catalytic oxidizers are usually used only

on gas streams with an organic vapor concentration <25 % of the LFL. Extremely

high temperature will damage the catalysts.

High cost and performance problems are related to physical and chemical

deterioration of the catalyst material. Certain metals can react or alloy with the

catalyst, resulting in permanent catalyst deactivation. Fast acting poisons include

mercury, phosphorus, arsenic, antimony, and bismuth. Slow acting poisons include

lead, zinc and tin. At temperatures above about 535 °C, even copper and iron are

capable of alloying with platinum catalyst, reducing its activity. Some materials,

principally sulfur and halogen compounds, have a high adsorptive affinity for some

catalytic surfaces, reducing the active sites available to the organic compounds.

10.6.6 Other Approaches to Volatile Organic Compounds

Control

When the concentrations of VOCs are relatively high, about 5000 ppmv, they can

be separated by VOC condensation, i.e., by cooling or pressurizing. It is cost-

effective for high concentration; however, for VOCs with low boiling point, process