Page 100 - Air and Gas Drilling Manual

P. 100

3-28 Air and Gas Drilling Manual

the very limber drill pipe. Their use as transitional stiffness elements reduces the

mechanical failures in the bottom drill pipe elements of the drill string. Heavy-

weight drill pipe is also used in directional drilling operations where drill collars can

be replaced by the heavy-weight pipe. Using heavy-weight drill pipe in place of drill

collars reduces the rotary torque and drag, and increases directional control.

3.4.3 Drill Rod

Small rotary drilling rigs often use drill rod as a drill pipe substitute. Drill rod

is used in mining, environmental, and geotechnical drilling operations. These rods

are available in 2 ft, 5 ft, and 10 ft lengths. They are used in both mud (or water)

and air drilling operations. There are two types of drill rods, wireline drill rods, and

conventional drill rods.

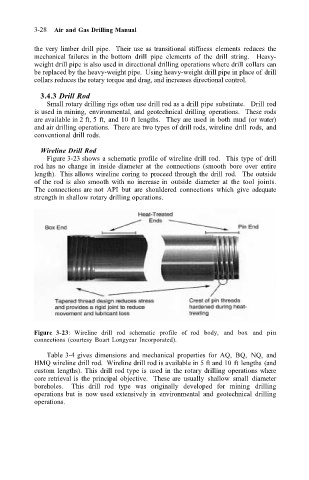

Wireline Drill Rod

Figure 3-23 shows a schematic profile of wireline drill rod. This type of drill

rod has no change in inside diameter at the connections (smooth bore over entire

length). This allows wireline coring to proceed through the drill rod. The outside

of the rod is also smooth with no increase in outside diameter at the tool joints.

The connections are not API but are shouldered connections which give adequate

strength in shallow rotary drilling operations.

Figure 3-23: Wireline drill rod schematic profile of rod body, and box and pin

connections (courtesy Boart Longyear Incorporated).

Table 3-4 gives dimensions and mechanical properties for AQ, BQ, NQ, and

HMQ wireline drill rod. Wireline drill rod is available in 5 ft and 10 ft lengths (and

custom lengths). This drill rod type is used in the rotary drilling operations where

core retrieval is the principal objective. These are usually shallow small diameter

boreholes. This drill rod type was originally developed for mining drilling

operations but is now used extensively in environmental and geotechnical drilling

operations.