Page 97 - Air and Gas Drilling Manual

P. 97

Chapter 3: Downhole Equipment 3-25

axial tension is the pipe body. Column (11) gives a torque of 55,453 ft-lb to give

torsion yield of the steel of the pipe body and Column (12) gives a torque of 44,673

ft-lb to give torsion yield of the steel of the tool joint box. Thus, the weakest part

of the drill pipe element to torque is the pipe body.

Table B-6 gives a summary of the API connections available for both drill

collars and drill pipe. These connections are all API recognized and are used by a

variety of fabricators of drill collars and drill pipe. The table gives the outside

diameter, inside diameter, and thread data for each connection type and size. Also

given are the detailed dimensions of the box and pin of each connection. These

dimensions are not used in machining box and pin connections. Readers are referred

to Reference 6 to obtain information regarding API connection dimensions and

tolerances for machine shop.

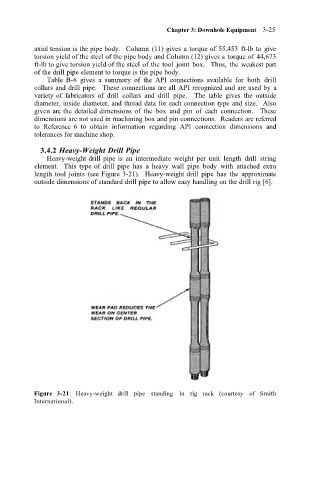

3.4.2 Heavy-Weight Drill Pipe

Heavy-weight drill pipe is an intermediate weight per unit length drill string

element. This type of drill pipe has a heavy wall pipe body with attached extra

length tool joints (see Figure 3-21). Heavy-weight drill pipe has the approximate

outside dimensions of standard drill pipe to allow easy handling on the drill rig [6].

Figure 3-21: Heavy-weight drill pipe standing in rig rack (courtesy of Smith

International).