Page 102 - Air and Gas Drilling Manual

P. 102

3-30 Air and Gas Drilling Manual

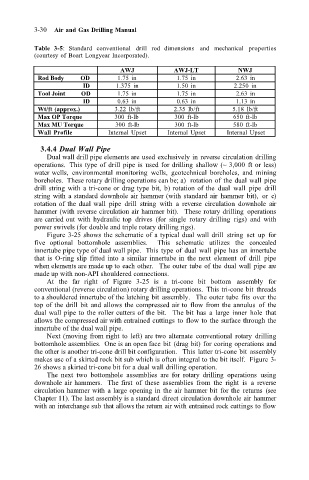

Table 3-5: Standard conventional drill rod dimensions and mechanical properties

(courtesy of Boart Longyear Incorporated).

AWJ AWJ-LT NWJ

Rod Body OD 1.75 in 1.75 in 2.63 in

ID 1.375 in 1.50 in 2.250 in

Tool Joint OD 1.75 in 1.75 in 2.63 in

ID 0.63 in 0.63 in 1.13 in

Wt/ft (approx.) 3.22 lb/ft 2.35 lb/ft 5.18 lb/ft

Max OP Torque 300 ft-lb 300 ft-lb 650 ft-lb

Max MU Torque 300 ft-lb 300 ft-lb 580 ft-lb

Wall Profile Internal Upset Internal Upset Internal Upset

3.4.4 Dual Wall Pipe

Dual wall drill pipe elements are used exclusively in reverse circulation drilling

operations. This type of drill pipe is used for drilling shallow (~ 3,000 ft or less)

water wells, environmental monitoring wells, geotechnical boreholes, and mining

boreholes. These rotary drilling operations can be; a) rotation of the dual wall pipe

drill string with a tri-cone or drag type bit, b) rotation of the dual wall pipe drill

string with a standard downhole air hammer (with standard air hammer bit), or c)

rotation of the dual wall pipe drill string with a reverse circulation downhole air

hammer (with reverse circulation air hammer bit). These rotary drilling operations

are carried out with hydraulic top drives (for single rotary drilling rigs) and with

power swivels (for double and triple rotary drilling rigs).

Figure 3-25 shows the schematic of a typical dual wall drill string set up for

five optional bottomhole assemblies. This schematic utilizes the concealed

innertube pipe type of dual wall pipe. This type of dual wall pipe has an innertube

that is O-ring slip fitted into a similar innertube in the next element of drill pipe

when elements are made up to each other. The outer tube of the dual wall pipe are

made up with non-API shouldered connections.

At the far right of Figure 3-25 is a tri-cone bit bottom assembly for

conventional (reverse circulation) rotary drilling operations. This tri-cone bit threads

to a shouldered innertube of the latching bit assembly. The outer tube fits over the

top of the drill bit and allows the compressed air to flow from the annulus of the

dual wall pipe to the roller cutters of the bit. The bit has a large inner hole that

allows the compressed air with entrained cuttings to flow to the surface through the

innertube of the dual wall pipe.

Next (moving from right to left) are two alternate conventional rotary drilling

bottomhole assemblies. One is an open face bit (drag bit) for coring operations and

the other is another tri-cone drill bit configuration. This latter tri-cone bit assembly

makes use of a skirted rock bit sub which is often integral to the bit itself. Figure 3-

26 shows a skirted tri-cone bit for a dual wall drilling operation.

The next two bottomhole assemblies are for rotary drilling operations using

downhole air hammers. The first of these assemblies from the right is a reverse

circulation hammer with a large opening in the air hammer bit for the returns (see

Chapter 11). The last assembly is a standard direct circulation downhole air hammer

with an interchange sub that allows the return air with entrained rock cuttings to flow