Page 107 - Air and Gas Drilling Manual

P. 107

Chapter 3: Downhole Equipment 3-35

In general dual wall pipe elements are structurally very rigid and stiff. Thus,

this type of pipe can be used in compression. This eliminates the need for heavy

drill collars to place WOB in a reverse circulation, dual wall pipe drilling operation.

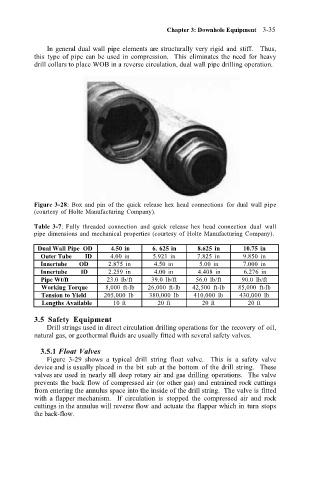

Figure 3-28: Box and pin of the quick release hex head connections for dual wall pipe

(courtesy of Holte Manufacturing Company).

Table 3-7: Fully threaded connection and quick release hex head connection dual wall

pipe dimensions and mechanical properties (courtesy of Holte Manufacturing Company).

Dual Wall Pipe OD 4.50 in 6. 625 in 8.625 in 10.75 in

Outer Tube ID 4.00 in 5.921 in 7.825 in 9.850 in

Innertube OD 2.875 in 4.50 in 5.00 in 7.000 in

Innertube ID 2.259 in 4.00 in 4.408 in 6.276 in

Pipe Wt/ft 23.0 lb/ft 39.0 lb/ft 56.0 lb/ft 90.0 lb/ft

Working Torque 8,000 ft-lb 26,000 ft-lb 42,500 ft-lb 85,000 ft-lb

Tension to Yield 205,000 lb 380,000 lb 410,000 lb 430,000 lb

Lengths Available 10 ft 20 ft 20 ft 20 ft

3.5 Safety Equipment

Drill strings used in direct circulation drilling operations for the recovery of oil,

natural gas, or geothermal fluids are usually fitted with several safety valves.

3.5.1 Float Valves

Figure 3-29 shows a typical drill string float valve. This is a safety valve

device and is usually placed in the bit sub at the bottom of the drill string. These

valves are used in nearly all deep rotary air and gas drilling operations. The valve

prevents the back flow of compressed air (or other gas) and entrained rock cuttings

from entering the annulus space into the inside of the drill string. The valve is fitted

with a flapper mechanism. If circulation is stopped the compressed air and rock

cuttings in the annulus will reverse flow and actuate the flapper which in turn stops

the back-flow.