Page 108 - Air and Gas Drilling Manual

P. 108

3-36 Air and Gas Drilling Manual

Fire float valves and fire stop valves are used only for oil and natural gas

recovery drilling operations.

The fire stop valves are placed just above the drill bit and along the drill string

at several positions. These valves have a zinc ring that holds back a spring-loaded

flapper mechanism (like the float valve above) allowing air circulation from the

surface. Wireline equipment can be run through these valves when the fire stop is in

the normal open position. Figure 3-30 shows the schematic of the fire stop valve.

This valve is basically the reverse of the float valve (compare Figures 3-29 and 3-

30).

A single fire float can be installed at the bottom of the drill string. This valve

is usually installed in the bit sub just above the drill bit. In normal operation, air

flow pressure from circulation forces a spring-loaded piston down allowing the air to

circulate. When design temperature is exceeded, a zinc ring melts which in turn

allows a sleeve to close over air ports stopping circulation and the supply of air to

the bottom of the borehole.

3.5.2 Kelly Sub Valves

At the top of the drill string (just above the kelly) is a kelly cock sub which is

fitted with a ball valve (see Figure 3-1). In the event of a subsurface blowout, the

kelly cock’s ball valve can be closed and the sub left made up to the top of the kelly.

With the ball valve closed, a pressure gauge can be made up to the top of the sub.

Using this pressure gauge, the ball valve can be opened and vital pressure

information obtained for the pressure inside the drill string (together with casing head

annulus pressure). This information is needed to design the well control procedure.

1

2

3

4

5

6

8

7

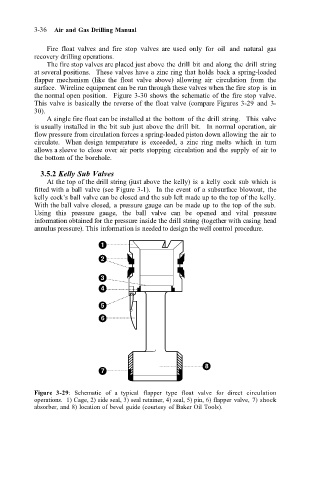

Figure 3-29: Schematic of a typical flapper type float valve for direct circulation

operations. 1) Cage, 2) side seal, 3) seal retainer, 4) seal, 5) pin, 6) flapper valve, 7) shock

absorber, and 8) location of bevel guide (courtesy of Baker Oil Tools).