Page 481 - Air and Gas Drilling Manual

P. 481

10-6 Air and Gas Drilling Manual

makes it difficulty to maintain a underbalanced condtions.

• The flow down the inside of the drill string is two phase flow and,

therefore, high pipe friction losses are present. The high friction losses

result in high pump and compressor pressures during injection.

• The gas phase in the stable foam attenuates the pulses of conventional

(measure-while-drilling) MWD systems. Therefore, conventional mud

pulse telemetry MWD cannot be used.

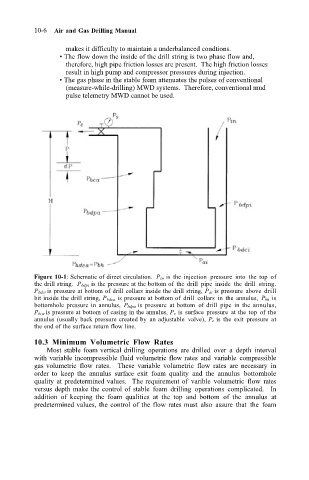

Figure 10-1: Schematic of direct circulation. P in is the injection pressure into the top of

the drill string. P bdpi is the pressure at the bottom of the drill pipe inside the drill string.

P bdci is pressure at bottom of drill collars inside the drill string, P ai is pressure above drill

bit inside the drill string, P bdca is pressure at bottom of drill collars in the annulus, P bh is

bottomhole pressure in annulus, P bdpa is pressure at bottom of drill pipe in the annulus,

P bca is pressure at bottom of casing in the annulus, P s is surface pressure at the top of the

annulus (usually back pressure created by an adjustable valve), P e is the exit pressure at

the end of the surface return flow line.

10.3 Minimum Volumetric Flow Rates

Most stable foam vertical drilling operations are drilled over a depth interval

with variable incompressible fluid volumetric flow rates and variable compressible

gas volumetric flow rates. These variable volumetric flow rates are necessary in

order to keep the annulus surface exit foam quality and the annulus bottomhole

quality at predetermined values. The requirement of varible volumetric flow rates

versus depth make the control of stable foam drilling operations complicated. In

addition of keeping the foam qualities at the top and bottom of the annulus at

predetermined values, the control of the flow rates must also assure that the foam