Page 56 - Air and Gas Drilling Manual

P. 56

2-6 Air and Gas Drilling Manual

pressure gauge. For air drilling operations this mud gauge must be replaced with a

high quality gas gauge having the appropriate pressure range.

2.2.7 Volumetric FlowRate Meters

No driller would carry out a mud drilling operation without knowing the

volumetric flow rate of mud being circulated to the well. The volumetric flow rate

from a mud pump can be easily assessed by either counting strokes per minute of the

mud pump (and knowing the capacity of the pump in gallons per stroke and then

calculating the output of the pump in gallons per minute), or by providing the rig

floor with an accurate volumetric flow rate gauge.

The volumetric flow rate of air (or other gases) to the well is vital knowledge for

a successful drilling operation and its knowledge must also be made available to the

rig personnel. Volumetric flow rate of air (or other gases) is referenced to the

atmospheric conditions of the air entering the primary compressor. At sea level

locations the volumetric flow rate is given as standard cubic feet per minute (scfm).

At locations above sea level the volumetric flow rate is given as actual cubic feet per

minute (acfm).

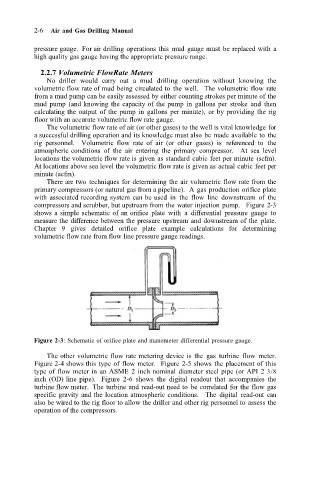

There are two techniques for determining the air volumetric flow rate from the

primary compressors (or natural gas from a pipeline). A gas production orifice plate

with associated recording system can be used in the flow line downstream of the

compressors and scrubber, but upstream from the water injection pump. Figure 2-3

shows a simple schematic of an orifice plate with a differential pressure gauge to

measure the difference between the pressure upstream and downstream of the plate.

Chapter 9 gives detailed orifice plate example calculations for determining

volumetric flow rate from flow line pressure gauge readings.

Figure 2-3: Schematic of orifice plate and manometer differential pressure gauge.

The other volumetric flow rate metering device is the gas turbine flow meter.

Figure 2-4 shows this type of flow meter. Figure 2-5 shows the placement of this

type of flow meter in an ASME 2 inch nominal diameter steel pipe (or API 2 3/8

inch (OD) line pipe). Figure 2-6 shows the digital readout that accompanies the

turbine flow meter. The turbine and read-out need to be correlated for the flow gas

specific gravity and the location atmospheric conditions. The digital read-out can

also be wired to the rig floor to allow the driller and other rig personnel to assess the

operation of the compressors.