Page 74 - Air and Gas Drilling Manual

P. 74

3-2 Air and Gas Drilling Manual

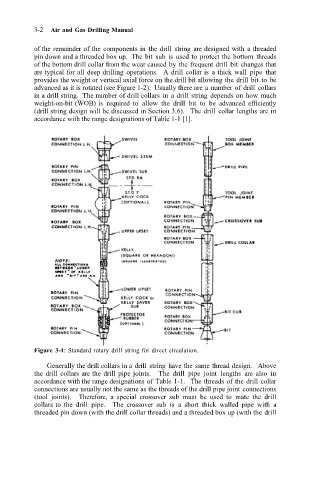

of the remainder of the components in the drill string are designed with a threaded

pin down and a threaded box up. The bit sub is used to protect the bottom threads

of the bottom drill collar from the wear caused by the frequent drill bit changes that

are typical for all deep drilling operations. A drill collar is a thick wall pipe that

provides the weight or vertical axial force on the drill bit allowing the drill bit to be

advanced as it is rotated (see Figure 1-2). Usually there are a number of drill collars

in a drill string. The number of drill collars in a drill string depends on how much

weight-on-bit (WOB) is required to allow the drill bit to be advanced efficiently

(drill string design will be discussed in Section 3.6). The drill collar lengths are in

accordance with the range designations of Table 1-1 [1].

Figure 3-1: Standard rotary drill string for direct circulation.

Generally the drill collars in a drill string have the same thread design. Above

the drill collars are the drill pipe joints. The drill pipe joint lengths are also in

accordance with the range designations of Table 1-1. The threads of the drill collar

connections are usually not the same as the threads of the drill pipe joint connections

(tool joints). Therefore, a special crossover sub must be used to mate the drill

collars to the drill pipe. The crossover sub is a short thick walled pipe with a

threaded pin down (with the drill collar threads) and a threaded box up (with the drill