Page 197 - Air and gas Drilling Field Guide 3rd Edition

P. 197

188 CHAPTER 8 Air, Gas, and Unstable Foam Drilling

G

FIxed Bed

H

F

Log Δp/L G 3 G 2 C

G 1 B

G=0

D

E

A

Log v

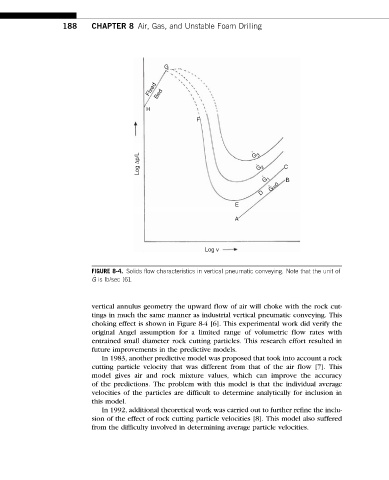

FIGURE 8-4. Solids flow characteristics in vertical pneumatic conveying. Note that the unit of

_

G is lb/sec [6].

vertical annulus geometry the upward flow of air will choke with the rock cut-

tings in much the same manner as industrial vertical pneumatic conveying. This

choking effect is shown in Figure 8-4 [6]. This experimental work did verify the

original Angel assumption for a limited range of volumetric flow rates with

entrained small diameter rock cutting particles. This research effort resulted in

future improvements in the predictive models.

In 1983, another predictive model was proposed that took into account a rock

cutting particle velocity that was different from that of the air flow [7]. This

model gives air and rock mixture values, which can improve the accuracy

of the predictions. The problem with this model is that the individual average

velocities of the particles are difficult to determine analytically for inclusion in

this model.

In 1992, additional theoretical work was carried out to further refine the inclu-

sion of the effect of rock cutting particle velocities [8]. This model also suffered

from the difficulty involved in determining average particle velocities.