Page 20 - Air and gas Drilling Field Guide 3rd Edition

P. 20

2.1 Rotary Drilling 11

is carried out almost exclusively in sedimentary rock. Boreholes for the recovery

of geothermal steam and water are constructed in all three rock types. The rotary

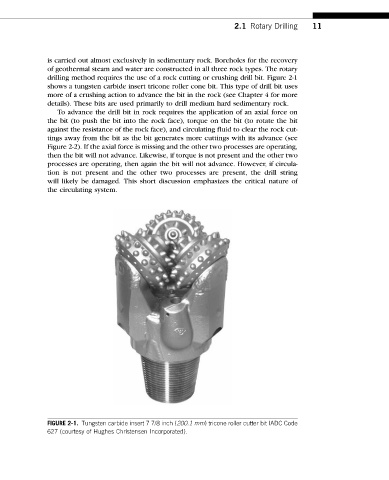

drilling method requires the use of a rock cutting or crushing drill bit. Figure 2-1

shows a tungsten carbide insert tricone roller cone bit. This type of drill bit uses

more of a crushing action to advance the bit in the rock (see Chapter 4 for more

details). These bits are used primarily to drill medium hard sedimentary rock.

To advance the drill bit in rock requires the application of an axial force on

the bit (to push the bit into the rock face), torque on the bit (to rotate the bit

against the resistance of the rock face), and circulating fluid to clear the rock cut-

tings away from the bit as the bit generates more cuttings with its advance (see

Figure 2-2). If the axial force is missing and the other two processes are operating,

then the bit will not advance. Likewise, if torque is not present and the other two

processes are operating, then again the bit will not advance. However, if circula-

tion is not present and the other two processes are present, the drill string

will likely be damaged. This short discussion emphasizes the critical nature of

the circulating system.

FIGURE 2-1. Tungsten carbide insert 7 7/8 inch (200.1 mm) tricone roller cutter bit IADC Code

627 (courtesy of Hughes Christensen Incorporated).