Page 21 - Air and gas Drilling Field Guide 3rd Edition

P. 21

12 CHAPTER 2 Air and Gas Versus Mud

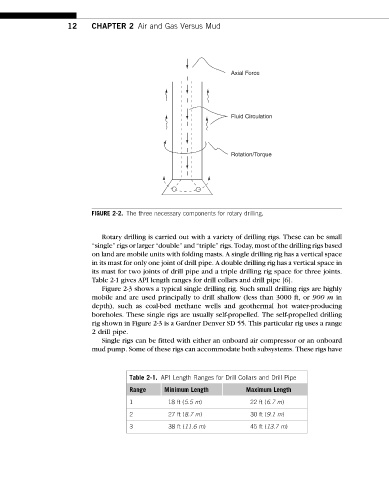

Axial Force

Fluid Circulation

Rotation/Torque

FIGURE 2-2. The three necessary components for rotary drilling.

Rotary drilling is carried out with a variety of drilling rigs. These can be small

“single” rigs or larger “double” and “triple” rigs. Today, most of the drilling rigs based

on land are mobile units with folding masts. A single drilling rig has a vertical space

in its mast for only one joint of drill pipe. A double drilling rig has a vertical space in

its mast for two joints of drill pipe and a triple drilling rig space for three joints.

Table 2-1 gives API length ranges for drill collars and drill pipe [6].

Figure 2-3 shows a typical single drilling rig. Such small drilling rigs are highly

mobile and are used principally to drill shallow (less than 3000 ft, or 900 m in

depth), such as coal-bed methane wells and geothermal hot water-producing

boreholes. These single rigs are usually self-propelled. The self-propelled drilling

rig shown in Figure 2-3 is a Gardner Denver SD 55. This particular rig uses a range

2 drill pipe.

Single rigs can be fitted with either an onboard air compressor or an onboard

mud pump. Some of these rigs can accommodate both subsystems. These rigs have

Table 2-1. API Length Ranges for Drill Collars and Drill Pipe

Range Minimum Length Maximum Length

1 18 ft (5.5 m) 22 ft (6.7 m)

2 27 ft (8.7 m) 30 ft (9.1 m)

3 38 ft (11.6 m) 45 ft (13.7 m)