Page 23 - Air and gas Drilling Field Guide 3rd Edition

P. 23

14 CHAPTER 2 Air and Gas Versus Mud

CROWN

BLOCK

MAST

“CROWS

NEST”

TRAVELING

AIR COMPRESSOR BLOCK

SWIVEL

HOSE

MUD PUMP

KELLY

HYDRAULIC

RESERVOIR

DOUBLE-DRUM

DRAW WORKS ROTARY

WITH SANDREEL

TABLE

CATHEAD

SUPPORT JACKS

DRILLER’S STATION

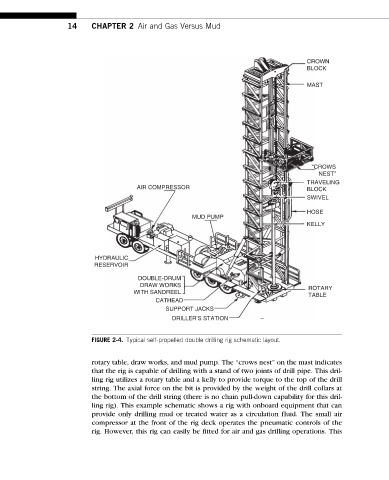

FIGURE 2-4. Typical self-propelled double drilling rig schematic layout.

rotary table, draw works, and mud pump. The “crows nest” on the mast indicates

that the rig is capable of drilling with a stand of two joints of drill pipe. This dril-

ling rig utilizes a rotary table and a kelly to provide torque to the top of the drill

string. The axial force on the bit is provided by the weight of the drill collars at

the bottom of the drill string (there is no chain pull-down capability for this dril-

ling rig). This example schematic shows a rig with onboard equipment that can

provide only drilling mud or treated water as a circulation fluid. The small air

compressor at the front of the rig deck operates the pneumatic controls of the

rig. However, this rig can easily be fitted for air and gas drilling operations. This