Page 27 - Air and gas Drilling Field Guide 3rd Edition

P. 27

18 CHAPTER 2 Air and Gas Versus Mud

ROTARY HOSE

STANDPIPE

SWIVEL

COMPRESSOR

ROTATING

HEAD

KELLY

BLOOEY

LINE

DRILL PIPE

DRILL COLLAR

BIT

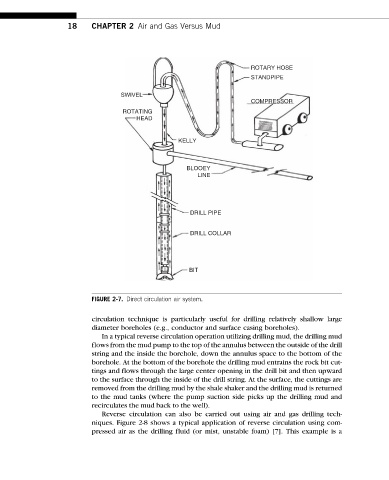

FIGURE 2-7. Direct circulation air system.

circulation technique is particularly useful for drilling relatively shallow large

diameter boreholes (e.g., conductor and surface casing boreholes).

In a typical reverse circulation operation utilizing drilling mud, the drilling mud

flows from the mud pump to the top of the annulus between the outside of the drill

string and the inside the borehole, down the annulus space to the bottom of the

borehole. At the bottom of the borehole the drilling mud entrains the rock bit cut-

tings and flows through the large center opening in the drill bit and then upward

to the surface through the inside of the drill string. At the surface, the cuttings are

removed from the drilling mud by the shale shaker and the drilling mud is returned

to the mud tanks (where the pump suction side picks up the drilling mud and

recirculates the mud back to the well).

Reverse circulation can also be carried out using air and gas drilling tech-

niques. Figure 2-8 shows a typical application of reverse circulation using com-

pressed air as the drilling fluid (or mist, unstable foam) [7]. This example is a