Page 30 - Air and gas Drilling Field Guide 3rd Edition

P. 30

2.3 Comparison of Mud and Air Drilling 21

2.3.1 Advantages and Disadvantages

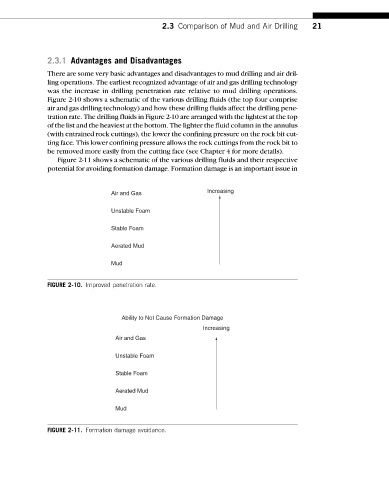

There are some very basic advantages and disadvantages to mud drilling and air dril-

ling operations. The earliest recognized advantage of air and gas drilling technology

was the increase in drilling penetration rate relative to mud drilling operations.

Figure 2-10 shows a schematic of the various drilling fluids (the top four comprise

air and gas drilling technology) and how these drilling fluids affect the drilling pene-

tration rate. The drilling fluids in Figure 2-10 are arranged with the lightest at the top

of the list and the heaviest at the bottom. The lighter the fluid column in the annulus

(with entrained rock cuttings), the lower the confining pressure on the rock bit cut-

ting face. This lower confining pressure allows the rock cuttings from the rock bit to

be removed more easily from the cutting face (see Chapter 4 for more details).

Figure 2-11 shows a schematic of the various drilling fluids and their respective

potential for avoiding formation damage. Formation damage is an important issue in

Increasing

Air and Gas

Unstable Foam

Stable Foam

Aerated Mud

Mud

FIGURE 2-10. Improved penetration rate.

Ability to Not Cause Formation Damage

Increasing

Air and Gas

Unstable Foam

Stable Foam

Aerated Mud

Mud

FIGURE 2-11. Formation damage avoidance.