Page 52 - Air and gas Drilling Field Guide 3rd Edition

P. 52

3.3 Wellhead Equipment 43

3.3 WELLHEAD EQUIPMENT

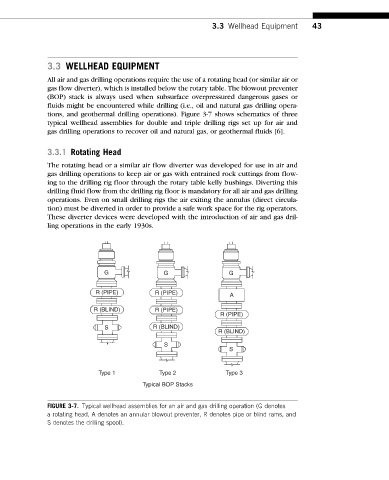

All air and gas drilling operations require the use of a rotating head (or similar air or

gas flow diverter), which is installed below the rotary table. The blowout preventer

(BOP) stack is always used when subsurface overpressured dangerous gases or

fluids might be encountered while drilling (i.e., oil and natural gas drilling opera-

tions, and geothermal drilling operations). Figure 3-7 shows schematics of three

typical wellhead assemblies for double and triple drilling rigs set up for air and

gas drilling operations to recover oil and natural gas, or geothermal fluids [6].

3.3.1 Rotating Head

The rotating head or a similar air flow diverter was developed for use in air and

gas drilling operations to keep air or gas with entrained rock cuttings from flow-

ing to the drilling rig floor through the rotary table kelly bushings. Diverting this

drilling fluid flow from the drilling rig floor is mandatory for all air and gas drilling

operations. Even on small drilling rigs the air exiting the annulus (direct circula-

tion) must be diverted in order to provide a safe work space for the rig operators.

These diverter devices were developed with the introduction of air and gas dril-

ling operations in the early 1930s.

G G G

R (PIPE) R (PIPE)

A

R (BLIND) R (PIPE)

R (PIPE)

S R (BLIND)

R (BLIND)

S

S

Type 1 Type 2 Type 3

Typical BOP Stacks

FIGURE 3-7. Typical wellhead assemblies for an air and gas drilling operation (G denotes

a rotating head, A denotes an annular blowout preventer, R denotes pipe or blind rams, and

S denotes the drilling spool).