Page 235 - Aircraft Stuctures for Engineering Student

P. 235

7.1 Materials of aircraft construction 219

5 45- Carbon Fibre

cross Ply Outer wrap

Greev Nomex

Honeycomb Care

Foarnmg Adhesive

Cross Ply Rear Wall

Slaiflless Steel 545' Carbon Fibre

Erowon Shleld

Cross Ply Inner Wrap

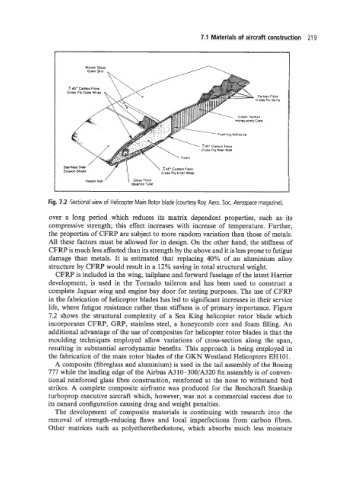

Fig. 7.2 Sectional view of Helicopter Main Rotor blade (courtesy Roy. Aero. SOC. Aerospace magazine).

over a long period which reduces its matrix dependent properties, such as its

compressive strength; this effect increases with increase of temperature. Further,

the properties of CFRP are subject to more random variation than those of metals.

All these factors must be allowed for in design. On the other hand, the stiffness of

CFRP is much less affected than its strength by the above and it is less prone to fatigue

damage than metals. It is estimated that replacing 40% of an aluminium alloy

structure by CFRP would result in a 12% saving in total structural weight.

CFRP is included in the wing, tailplane and forward fuselage of the latest Harrier

development, is used in the Tornado taileron and has been used to construct a

complete Jaguar wing and engine bay door for testing purposes. The use of CFRP

in the fabrication of helicopter blades has led to significant increases in their service

life, where fatigue resistance rather than stiffness is of primary importance. Figure

7.2 shows the structural complexity of a Sea King helicopter rotor blade which

incorporates CFRP, GRP, stainless steel, a honeycomb core and foam filling. An

additional advantage of the use of composites for helicopter rotor blades is that the

moulding techniques employed allow variations of cross-section along the span,

resulting in substantial aerodynamic benefits. This approach is being employed in

the fabrication of the main rotor blades of the GKN Westland Helicopters EH101.

A composite (fibreglass and aluminium) is used in the tail assembly of the Boeing

777 while the leading edge of the Airbus A3 10-300/A320 fin assembly is of conven-

tional reinforced glass fibre construction, reinforced at the nose to withstand bird

strikes. A complete composite airframe was produced for the Beechcraft Starship

turboprop executive aircraft which, however, was not a commercial success due to

its canard configuration causing drag and weight penalties.

The development of composite materials is continuing with research into the

removal of strength-reducing flaws and local imperfections from carbon fibres.

Other matrices such as polyetheretherketone, which absorbs much less moisture