Page 249 - Aircraft Stuctures for Engineering Student

P. 249

230 Principles of stressed skin construction

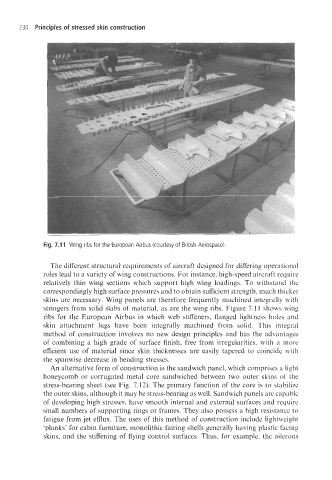

Fig. 7.1 1 Wing ribs for the European Airbus (courtesy of British Aerospace).

The different structural requirements of aircraft designed for differing operational

roles lead to a variety of wing constructions. For instance, high-speed aircraft require

relatively thin wing sections which support high wing loadings. To withstand the

correspondingly high surface pressures and to obtain sufficient strength, much thicker

skins are necessary. Wing panels are therefore frequently machined integrally with

stringers from solid slabs of material, as are the wing ribs. Figure 7.11 shows wing

ribs for the European Airbus in which web stiffeners, flanged lightness holes and

skin attachment lugs have been integrally machined from solid. This integral

method of construction involves no new design principles and has the advantages

of combining a high grade of surface finish, free from irregularities, with a more

efficient use of material since skin thicknesses are easily tapered to coincide with

the spanwise decrease in bending stresses.

An alternative form of construction is the sandwich panel, which comprises a light

honeycomb or corrugated metal core sandwiched between two outer skins of the

stress-bearing sheet (see Fig. 7.12). The primary function of the core is to stabilize

the outer skins, although it may be stress-bearing as well. Sandwich panels are capable

of developing high stresses, have smooth internal and external surfaces and require

small numbers of supporting rings or frames. They also possess a high resistance to

fatigue from jet efflux. The uses of this method of construction include lightweight

‘planks’ for cabin furniture, monolithic fairing shells generally having plastic facing

skins, and the stiffening of flying control surfaces. Thus, for example, the ailerons