Page 123 - Alternative Energy Systems in Building Design

P. 123

ROOF-MOUNTED INSTALLATIONS 99

TIE DOWN

BRACKET

PV PANEL PV PANEL

UNIRACK RAIL

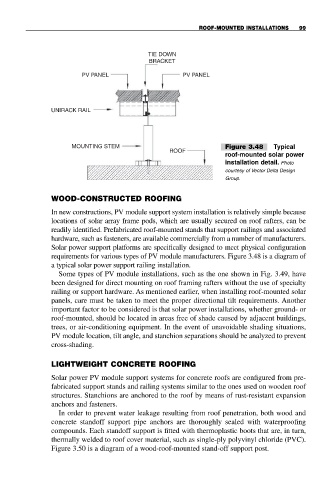

MOUNTING STEM Figure 3.48 Typical

ROOF

roof-mounted solar power

installation detail. Photo

courtesy of Vector Delta Design

Group.

WOOD-CONSTRUCTED ROOFING

In new constructions, PV module support system installation is relatively simple because

locations of solar array frame pods, which are usually secured on roof rafters, can be

readily identified. Prefabricated roof-mounted stands that support railings and associated

hardware, such as fasteners, are available commercially from a number of manufacturers.

Solar power support platforms are specifically designed to meet physical configuration

requirements for various types of PV module manufacturers. Figure 3.48 is a diagram of

a typical solar power support railing installation.

Some types of PV module installations, such as the one shown in Fig. 3.49, have

been designed for direct mounting on roof framing rafters without the use of specialty

railing or support hardware. As mentioned earlier, when installing roof-mounted solar

panels, care must be taken to meet the proper directional tilt requirements. Another

important factor to be considered is that solar power installations, whether ground- or

roof-mounted, should be located in areas free of shade caused by adjacent buildings,

trees, or air-conditioning equipment. In the event of unavoidable shading situations,

PV module location, tilt angle, and stanchion separations should be analyzed to prevent

cross-shading.

LIGHTWEIGHT CONCRETE ROOFING

Solar power PV module support systems for concrete roofs are configured from pre-

fabricated support stands and railing systems similar to the ones used on wooden roof

structures. Stanchions are anchored to the roof by means of rust-resistant expansion

anchors and fasteners.

In order to prevent water leakage resulting from roof penetration, both wood and

concrete standoff support pipe anchors are thoroughly sealed with waterproofing

compounds. Each standoff support is fitted with thermoplastic boots that are, in turn,

thermally welded to roof cover material, such as single-ply polyvinyl chloride (PVC).

Figure 3.50 is a diagram of a wood-roof-mounted stand-off support post.