Page 122 - Alternative Energy Systems in Building Design

P. 122

98 SOLAR POWER SYSTEM PHYSICS AND TECHNOLOGIES

frames that use rustproof railings, such as galvanized Unistrut or commercially avail-

able aluminum or stainless-steel angle channels, and fastening hardware, such as nuts,

bolts, and washers. Prefabricated solar power support systems are also available from

UniRac and several other manufacturers.

When installing solar support pedestals, also known as stanchions, attention must

be paid to structural design requirements. Solar power stanchions and pedestals must

be designed by a qualified registered professional engineer. Solar support structures

must take into consideration prevailing geographic and atmospheric conditions, such

as maximum wind gusts, flood conditions, and soil erosion.

Typical ground-mounted solar power installations include agricultural grounds,

parks and outdoor recreational facilities, carports, and large commercial solar power-

generating facilities, also known as solar farms. Most solar farms are owned and oper-

ated by electric energy-generating entities. Prior to the installation of a solar power

system, structural and electrical plans must be reviewed by local electrical service

authorities, such as building and safety departments.

Roof-Mounted Installations

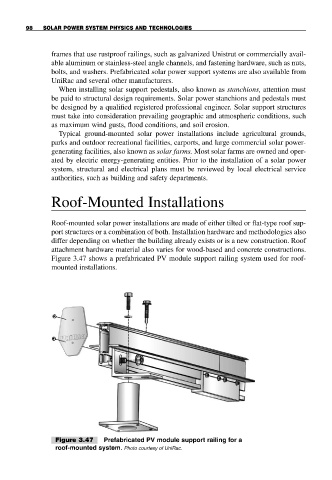

Roof-mounted solar power installations are made of either tilted or flat-type roof sup-

port structures or a combination of both. Installation hardware and methodologies also

differ depending on whether the building already exists or is a new construction. Roof

attachment hardware material also varies for wood-based and concrete constructions.

Figure 3.47 shows a prefabricated PV module support railing system used for roof-

mounted installations.

Figure 3.47 Prefabricated PV module support railing for a

roof-mounted system. Photo courtesy of UniRac.