Page 205 - An Introduction To Predictive Maintenance

P. 205

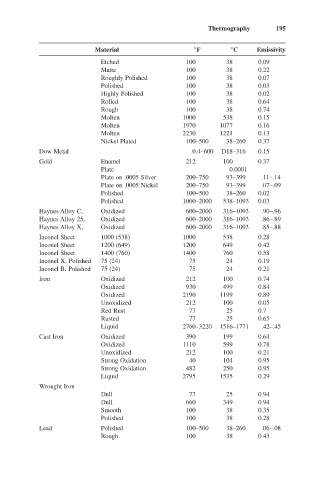

Thermography 195

Material °F °C Emissivity

Etched 100 38 0.09

Matte 100 38 0.22

Roughly Polished 100 38 0.07

Polished 100 38 0.03

Highly Polished 100 38 0.02

Rolled 100 38 0.64

Rough 100 38 0.74

Molten 1000 538 0.15

Molten 1970 1077 0.16

Molten 2230 1221 0.13

Nickel Plated 100–500 38–260 0.37

Dow Metal 0.4–600 D18–316 0.15

Gold Enamel 212 100 0.37

Plate 0.0001

Plate on .0005 Silver 200–750 93–399 .11–.14

Plate on .0005 Nickel 200–750 93–399 .07–.09

Polished 100–500 38–260 0.02

Polished 1000–2000 538–1093 0.03

Haynes Alloy C, Oxidized 600–2000 316–1093 .90–.96

Haynes Alloy 25, Oxidized 600–2000 316–1093 .86–.89

Haynes Alloy X, Oxidized 600–2000 316–1093 .85–.88

Inconel Sheet 1000 (538) 1000 538 0.28

Inconel Sheet 1200 (649) 1200 649 0.42

Inconel Sheet 1400 (760) 1400 760 0.58

Inconel X, Polished 75 (24) 75 24 0.19

Inconel B, Polished 75 (24) 75 24 0.21

Iron Oxidized 212 100 0.74

Oxidized 930 499 0.84

Oxidized 2190 1199 0.89

Unoxidized 212 100 0.05

Red Rust 77 25 0.7

Rusted 77 25 0.65

Liquid 2760–3220 1516–1771 .42–.45

Cast Iron Oxidized 390 199 0.64

Oxidized 1110 599 0.78

Unoxidized 212 100 0.21

Strong Oxidation 40 104 0.95

Strong Oxidation 482 250 0.95

Liquid 2795 1535 0.29

Wrought Iron

Dull 77 25 0.94

Dull 660 349 0.94

Smooth 100 38 0.35

Polished 100 38 0.28

Lead Polished 100–500 38–260 .06–.08

Rough 100 38 0.43