Page 207 - An Introduction To Predictive Maintenance

P. 207

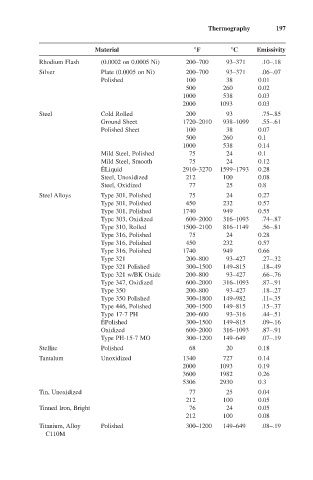

Thermography 197

Material °F °C Emissivity

Rhodium Flash (0.0002 on 0.0005 Ni) 200–700 93–371 .10–.18

Silver Plate (0.0005 on Ni) 200–700 93–371 .06–.07

Polished 100 38 0.01

500 260 0.02

1000 538 0.03

2000 1093 0.03

Steel Cold Rolled 200 93 .75–.85

Ground Sheet 1720–2010 938–1099 .55–.61

Polished Sheet 100 38 0.07

500 260 0.1

1000 538 0.14

Mild Steel, Polished 75 24 0.1

Mild Steel, Smooth 75 24 0.12

ÊLiquid 2910–3270 1599–1793 0.28

Steel, Unoxidized 212 100 0.08

Steel, Oxidized 77 25 0.8

Steel Alloys Type 301, Polished 75 24 0.27

Type 301, Polished 450 232 0.57

Type 301, Polished 1740 949 0.55

Type 303, Oxidized 600–2000 316–1093 .74–.87

Type 310, Rolled 1500–2100 816–1149 .56–.81

Type 316, Polished 75 24 0.28

Type 316, Polished 450 232 0.57

Type 316, Polished 1740 949 0.66

Type 321 200–800 93–427 .27–.32

Type 321 Polished 300–1500 149–815 .18–.49

Type 321 w/BK Oxide 200–800 93–427 .66–.76

Type 347, Oxidized 600–2000 316–1093 .87–.91

Type 350 200–800 93–427 .18–.27

Type 350 Polished 300–1800 149–982 .11–.35

Type 446, Polished 300–1500 149–815 .15–.37

Type 17-7 PH 200–600 93–316 .44–.51

ÊPolished 300–1500 149–815 .09–.16

Oxidized 600–2000 316–1093 .87–.91

Type PH-15-7 MO 300–1200 149–649 .07–.19

Stellite Polished 68 20 0.18

Tantalum Unoxidized 1340 727 0.14

2000 1093 0.19

3600 1982 0.26

5306 2930 0.3

Tin, Unoxidized 77 25 0.04

212 100 0.05

Tinned Iron, Bright 76 24 0.05

212 100 0.08

Titanium, Alloy Polished 300–1200 149–649 .08–.19

C110M