Page 106 - An Introduction to Analytical Atomic Spectrometry - L. Ebdon

P. 106

Page 89

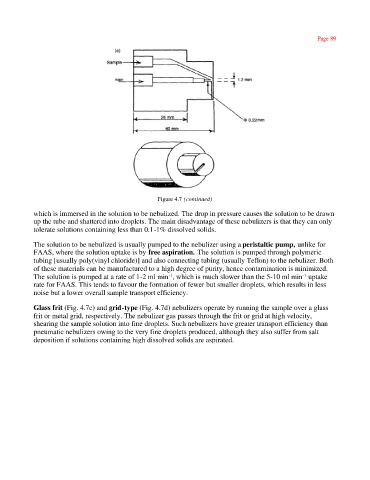

Figure 4.7 (continued)

which is immersed in the solution to be nebulized. The drop in pressure causes the solution to be drawn

up the tube and shattered into droplets. The main disadvantage of these nebulizers is that they can only

tolerate solutions containing less than 0.1-1% dissolved solids.

The solution to be nebulized is usually pumped to the nebulizer using a peristaltic pump, unlike for

FAAS, where the solution uptake is by free aspiration. The solution is pumped through polymeric

tubing [usually poly(vinyl chloride)] and also connecting tubing (usually Teflon) to the nebulizer. Both

of these materials can be manufactured to a high degree of purity, hence contamination is minimized.

The solution is pumped at a rate of 1-2 ml min , which is much slower than the 5-10 ml min uptake

-1

-1

rate for FAAS. This tends to favour the formation of fewer but smaller droplets, which results in less

noise but a lower overall sample transport efficiency.

Glass frit (Fig. 4.7c) and grid-type (Fig. 4.7d) nebulizers operate by running the sample over a glass

frit or metal grid, respectively. The nebulizer gas passes through the frit or grid at high velocity,

shearing the sample solution into fine droplets. Such nebulizers have greater transport efficiency than

pneumatic nebulizers owing to the very fine droplets produced, although they also suffer from salt

deposition if solutions containing high dissolved solids are aspirated.