Page 171 - Analysis and Design of Machine Elements

P. 171

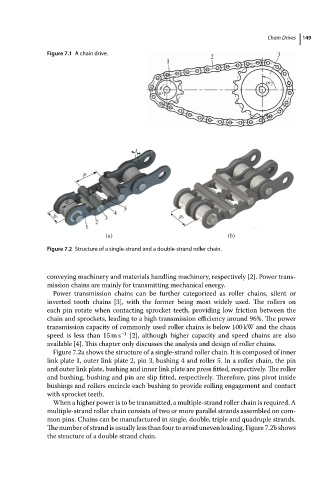

Figure 7.1 A chain drive. Chain Drives 149

3

2

1

ω 2

ω 1

(a) (b)

Figure 7.2 Structure of a single-strand and a double-strand roller chain.

conveying machinery and materials handling machinery, respectively [2]. Power trans-

mission chains are mainly for transmitting mechanical energy.

Power transmission chains can be further categorized as roller chains, silent or

inverted tooth chains [3], with the former being most widely used. The rollers on

each pin rotate when contacting sprocket teeth, providing low friction between the

chain and sprockets, leading to a high transmission efficiency around 96%. The power

transmission capacity of commonly used roller chains is below 100 kW and the chain

speed is less than 15 m s −1 [2], although higher capacity and speed chains are also

available [4]. This chapter only discusses the analysis and design of roller chains.

Figure 7.2a shows the structure of a single-strand roller chain. It is composed of inner

link plate 1, outer link plate 2, pin 3, bushing 4 and roller 5. In a roller chain, the pin

and outer link plate, bushing and inner link plate are press fitted, respectively. The roller

and bushing, bushing and pin are slip fitted, respectively. Therefore, pins pivot inside

bushings and rollers encircle each bushing to provide rolling engagement and contact

with sprocket teeth.

When a higher power is to be transmitted, a multiple-strand roller chain is required. A

multiple-strand roller chain consists of two or more parallel strands assembled on com-

mon pins. Chains can be manufactured in single, double, triple and quadruple strands.

The number of strand is usually less than four to avoid uneven loading. Figure 7.2b shows

the structure of a double strand chain.