Page 186 - Analysis and Design of Machine Elements

P. 186

Analysis and Design of Machine Elements

164

3

ω 2

2 3

1

ω 2

ω 1

2

(a)

1

ω 1

(b)

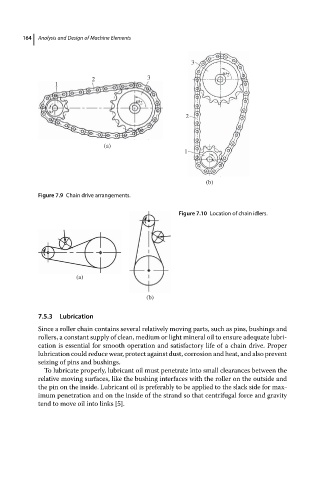

Figure 7.9 Chain drive arrangements.

Figure 7.10 Location of chain idlers.

(a)

(b)

7.5.3 Lubrication

Since a roller chain contains several relatively moving parts, such as pins, bushings and

rollers, a constant supply of clean, medium or light mineral oil to ensure adequate lubri-

cation is essential for smooth operation and satisfactory life of a chain drive. Proper

lubrication could reduce wear, protect against dust, corrosion and heat, and also prevent

seizing of pins and bushings.

To lubricate properly, lubricant oil must penetrate into small clearances between the

relative moving surfaces, like the bushing interfaces with the roller on the outside and

the pin on the inside. Lubricant oil is preferably to be applied to the slack side for max-

imum penetration and on the inside of the strand so that centrifugal force and gravity

tend to move oil into links [5].