Page 355 - Analysis and Design of Machine Elements

P. 355

Sliding Bearings

Friction between stationary surfaces is called static friction, while between moving 333

surfaces it is called kinetic friction. The two main kinds of kinetic friction are rolling

friction and sliding friction, appearing in contact bearings and sliding bearings, respec-

tively. The sliding friction between solid objects is dry friction, and between a solid and

a gas or liquid is fluid friction [6].

Fluid friction occurs under proper lubrication conditions. Consequently, lubrication

regimes are classified as boundary lubrication, mixed-film lubrication and hydrody-

namic lubrication, depending on the degree to which the lubricant separates sliding

surfaces.

In boundary lubrication, there is a very thin lubricant film adhering to the contact sur-

faces, and the highest asperities may be separated by lubricant films only several molec-

ular dimensions in thickness [1]. Local metal-to-metal surface contact is continuous

and extensive, which leads to a high rate of friction and wear. The surface films vary in

thickness from 1 to 10 nm. Typical values of friction coefficient are from 0.05 to 0.20 [2].

In mixed-film lubrication, surface peaks are intermittently in contact and there is par-

tial hydrodynamic support. The average film thickness in a mixed lubrication is less than

1 μmand greaterthan0.01 μm. The coefficients of friction commonly range from 0.004

to 0.1 [2].

The most desirable type of lubrication is obviously hydrodynamic lubrication. In

hydrodynamic lubrication, film thickness is significantly greater than the height of

surface roughness. Surfaces are completely separated by relatively thick lubricant film.

Both metal-to-metal contact and surface wear are prevented. The frictional losses

originate only within the lubricant film. Typical film thicknesses are from 0.008 to

0.02 mm. Coefficients of friction are within the range of 0.002–0.01 [2]. Hydrodynamic

lubrication is also called full-film, or fluid lubrication.

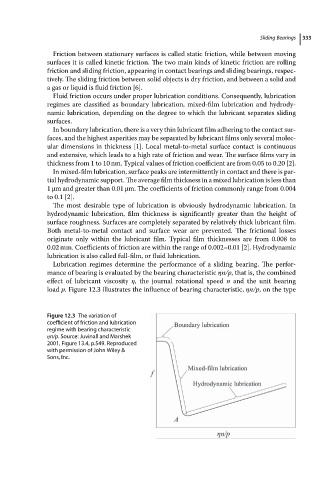

Lubrication regimes determine the performance of a sliding bearing. The perfor-

mance of bearing is evaluated by the bearing characteristic n/p,thatis, thecombined

effect of lubricant viscosity , the journal rotational speed n and the unit bearing

load p. Figure 12.3 illustrates the influence of bearing characteristic, n/p,onthe type

Figure 12.3 The variation of

coefficient of friction and lubrication

regime with bearing characteristic

n/p. Source: Juvinall and Marshek

2001, Figure 13.4, p.549. Reproduced

with permission of John Wiley &

Sons, Inc.