Page 389 - Analysis and Design of Machine Elements

P. 389

Couplings and Clutches

connected by a rigid coupling and are forced into alignment, the coupling, shafts and 367

bearings may subject to severe variable stresses, which may lead to rapid fatigue failure.

Ideally, a flexible coupling is a better choice as they can produce the greatest flexibility

without significant stresses induced in the connected shafts.

13.1.3 Types of Couplings

Mechanical couplings are typically divided into two broad categories: rigid couplings

and flexible couplings. Rigid couplings are only for accurate shaft alignment that

presents at initial installation and maintains during operation. If significant misalign-

ments occur, flexible couplings are preferred, as they can accommodate misalignments

and reduce stresses induced in the connected shafts, which may lead to early fatigue

failure. Table 13.1 shows typical types of rigid couplings.

Flanged couplings are probably the most common type of rigid connection. The cou-

pling flanges are mounted on the ends of the driving and driven shaft with keys and

are joined together by a group of precision bolted joints or ordinary bolted joints on

the bolt circle. A piloted boss is used for precise alignment if ordinary bolted joints are

used. An outer protective rim is often added to the flanges to provide a safety shield

for the bolt heads and nuts. While transmitting torque, the load is transmitted from the

driving shaft to its flange, through the bolts, into the mating flange and out to the driven

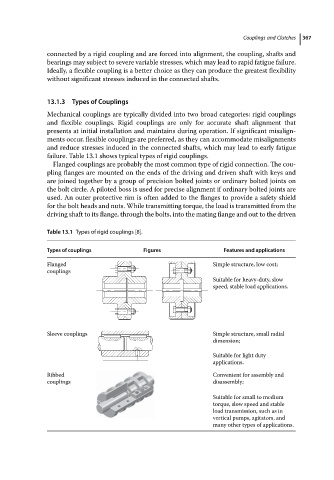

Table 13.1 Types of rigid couplings [8].

Types of couplings Figures Features and applications

Flanged Simple structure, low cost;

couplings

Suitable for heavy-duty, slow

speed, stable load applications.

Sleeve couplings Simple structure, small radial

dimension;

Suitable for light duty

applications.

Ribbed Convenient for assembly and

couplings disassembly;

Suitable for small to medium

torque, slow speed and stable

load transmission, such as in

vertical pumps, agitators, and

many other types of applications.