Page 427 - Analysis and Design of Machine Elements

P. 427

14.3.3 Analysis of Helical Torsion Springs Springs 405

14.3.3.1 Load-Deflection Relationship

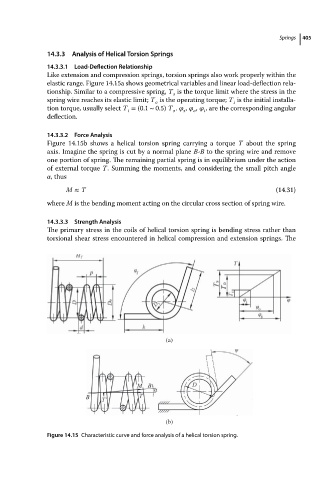

Like extension and compression springs, torsion springs also work properly within the

elastic range. Figure 14.15a shows geometrical variables and linear load-deflection rela-

tionship. Similar to a compressive spring, T is the torque limit where the stress in the

s

spring wire reaches its elastic limit; T is the operating torque; T is the initial installa-

i

o

tion torque, usually select T = (0.1 ∼ 0.5) T . , , , are the corresponding angular

i

i

s

o

o

deflection.

14.3.3.2 Force Analysis

Figure 14.15b shows a helical torsion spring carrying a torque T about the spring

axis. Imagine the spring is cut by a normal plane B-B to the spring wire and remove

one portion of spring. The remaining partial spring is in equilibrium under the action

of external torque T. Summing the moments, and considering the small pitch angle

,thus

M ≈ T (14.31)

where M is the bending moment acting on the circular cross section of spring wire.

14.3.3.3 Strength Analysis

The primary stress in the coils of helical torsion spring is bending stress rather than

torsional shear stress encountered in helical compression and extension springs. The

(a)

(b)

Figure 14.15 Characteristic curve and force analysis of a helical torsion spring.