Page 166 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 166

where high pressure is used, a temperature in excess of 400°C may be required in the reactor in

order to maintain all the species in the vapor phase.

4. Improve Selectivity: If competing reactions (series, parallel, or a combination of both) occur

and the different reactions have different activation energies, then the production of the desired

product may be favored by using a high temperature. Schemes for competing reactions are

covered in greater detail in many of the well-known texts on chemical reaction engineering, as

well as in Chapter 20.

For separators, we considered the following item of justification:

1. Obtain a Vapor Phase for Vapor-Liquid Equilibrium: This situation arises quite frequently

when high-boiling-point materials need to be distilled. An example is the distillation of crude

oil in which the bottom of the atmospheric column is typically operated in the region of 310°C

to 340°C (590°F to 645°F).

You would benefit by spending time to acquaint yourself with the information presented in Tables 6.1 to

6.3 and to convince yourself that you understand the justifications given in these tables. These tables

should not be considered an exhaustive list of possible reasons for operating in the ranges of special

concern. Instead, they represent a starting point in analyzing process conditions. As you discover other

explanations for reasons to operate equipment in the ranges of special concern you may wish to add them

to Tables 6.1–6.3. Additional blank entries are provided for this purpose.

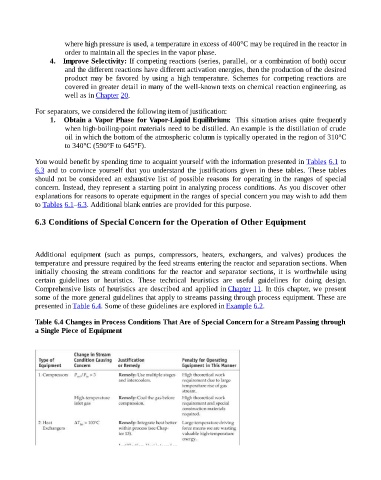

6.3 Conditions of Special Concern for the Operation of Other Equipment

Additional equipment (such as pumps, compressors, heaters, exchangers, and valves) produces the

temperature and pressure required by the feed streams entering the reactor and separation sections. When

initially choosing the stream conditions for the reactor and separator sections, it is worthwhile using

certain guidelines or heuristics. These technical heuristics are useful guidelines for doing design.

Comprehensive lists of heuristics are described and applied in Chapter 11. In this chapter, we present

some of the more general guidelines that apply to streams passing through process equipment. These are

presented in Table 6.4. Some of these guidelines are explored in Example 6.2.

Table 6.4 Changes in Process Conditions That Are of Special Concern for a Stream Passing through

a Single Piece of Equipment