Page 374 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 374

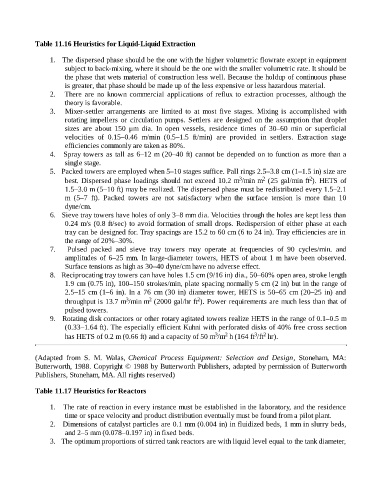

Table 11.16 Heuristics for Liquid-Liquid Extraction

1. The dispersed phase should be the one with the higher volumetric flowrate except in equipment

subject to back-mixing, where it should be the one with the smaller volumetric rate. It should be

the phase that wets material of construction less well. Because the holdup of continuous phase

is greater, that phase should be made up of the less expensive or less hazardous material.

2. There are no known commercial applications of reflux to extraction processes, although the

theory is favorable.

3. Mixer-settler arrangements are limited to at most five stages. Mixing is accomplished with

rotating impellers or circulation pumps. Settlers are designed on the assumption that droplet

sizes are about 150 μm dia. In open vessels, residence times of 30–60 min or superficial

velocities of 0.15–0.46 m/min (0.5–1.5 ft/min) are provided in settlers. Extraction stage

efficiencies commonly are taken as 80%.

4. Spray towers as tall as 6–12 m (20–40 ft) cannot be depended on to function as more than a

single stage.

5. Packed towers are employed when 5–10 stages suffice. Pall rings 2.5–3.8 cm (1–1.5 in) size are

3

2

2

best. Dispersed phase loadings should not exceed 10.2 m /min m (25 gal/min ft ). HETS of

1.5–3.0 m (5–10 ft) may be realized. The dispersed phase must be redistributed every 1.5–2.1

m (5–7 ft). Packed towers are not satisfactory when the surface tension is more than 10

dyne/cm.

6. Sieve tray towers have holes of only 3–8 mm dia. Velocities through the holes are kept less than

0.24 m/s (0.8 ft/sec) to avoid formation of small drops. Redispersion of either phase at each

tray can be designed for. Tray spacings are 15.2 to 60 cm (6 to 24 in). Tray efficiencies are in

the range of 20%–30%.

7. Pulsed packed and sieve tray towers may operate at frequencies of 90 cycles/min. and

amplitudes of 6–25 mm. In large-diameter towers, HETS of about 1 m have been observed.

Surface tensions as high as 30–40 dyne/cm have no adverse effect.

8. Reciprocating tray towers can have holes 1.5 cm (9/16 in) dia., 50–60% open area, stroke length

1.9 cm (0.75 in), 100–150 strokes/min, plate spacing normally 5 cm (2 in) but in the range of

2.5–15 cm (1–6 in). In a 76 cm (30 in) diameter tower, HETS is 50–65 cm (20–25 in) and

2

3

2

throughput is 13.7 m /min m (2000 gal/hr ft ). Power requirements are much less than that of

pulsed towers.

9. Rotating disk contactors or other rotary agitated towers realize HETS in the range of 0.1–0.5 m

(0.33–1.64 ft). The especially efficient Kuhni with perforated disks of 40% free cross section

3

2

3

2

has HETS of 0.2 m (0.66 ft) and a capacity of 50 m /m h (164 ft /ft hr).

(Adapted from S. M. Walas, Chemical Process Equipment: Selection and Design, Stoneham, MA:

Butterworth, 1988. Copyright © 1988 by Butterworth Publishers, adapted by permission of Butterworth

Publishers, Stoneham, MA. All rights reserved)

Table 11.17 Heuristics for Reactors

1. The rate of reaction in every instance must be established in the laboratory, and the residence

time or space velocity and product distribution eventually must be found from a pilot plant.

2. Dimensions of catalyst particles are 0.1 mm (0.004 in) in fluidized beds, 1 mm in slurry beds,

and 2–5 mm (0.078–0.197 in) in fixed beds.

3. The optimum proportions of stirred tank reactors are with liquid level equal to the tank diameter,