Page 372 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 372

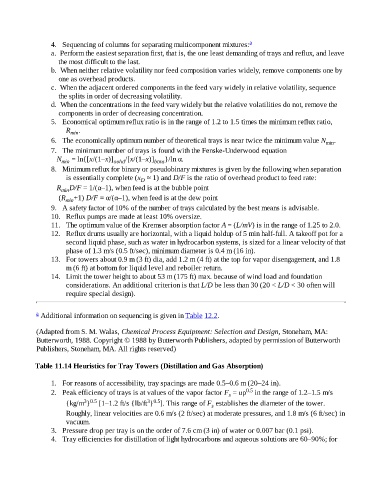

4. Sequencing of columns for separating multicomponent mixtures: a

a. Perform the easiest separation first, that is, the one least demanding of trays and reflux, and leave

the most difficult to the last.

b. When neither relative volatility nor feed composition varies widely, remove components one by

one as overhead products.

c. When the adjacent ordered components in the feed vary widely in relative volatility, sequence

the splits in order of decreasing volatility.

d. When the concentrations in the feed vary widely but the relative volatilities do not, remove the

components in order of decreasing concentration.

5. Economical optimum reflux ratio is in the range of 1.2 to 1.5 times the minimum reflux ratio,

R min .

6. The economically optimum number of theoretical trays is near twice the minimum value N min .

7. The minimum number of trays is found with the Fenske-Underwood equation

N min = ln{[x/(1–x)] oυhd /[x/(1–x)] btms }/ln α.

8. Minimum reflux for binary or pseudobinary mixtures is given by the following when separation

is essentially complete (x ≈ 1) and D/F is the ratio of overhead product to feed rate:

D

R min D/F = 1/(α–1), when feed is at the bubble point

(R min +1) D/F = α/(α–1), when feed is at the dew point

9. A safety factor of 10% of the number of trays calculated by the best means is advisable.

10. Reflux pumps are made at least 10% oversize.

11. The optimum value of the Kremser absorption factor A = (L/mV) is in the range of 1.25 to 2.0.

12. Reflux drums usually are horizontal, with a liquid holdup of 5 min half-full. A takeoff pot for a

second liquid phase, such as water in hydrocarbon systems, is sized for a linear velocity of that

phase of 1.3 m/s (0.5 ft/sec), minimum diameter is 0.4 m (16 in).

13. For towers about 0.9 m (3 ft) dia, add 1.2 m (4 ft) at the top for vapor disengagement, and 1.8

m (6 ft) at bottom for liquid level and reboiler return.

14. Limit the tower height to about 53 m (175 ft) max. because of wind load and foundation

considerations. An additional criterion is that L/D be less than 30 (20 < L/D < 30 often will

require special design).

a Additional information on sequencing is given in Table 12.2.

(Adapted from S. M. Walas, Chemical Process Equipment: Selection and Design, Stoneham, MA:

Butterworth, 1988. Copyright © 1988 by Butterworth Publishers, adapted by permission of Butterworth

Publishers, Stoneham, MA. All rights reserved)

Table 11.14 Heuristics for Tray Towers (Distillation and Gas Absorption)

1. For reasons of accessibility, tray spacings are made 0.5–0.6 m (20–24 in).

0.5

2. Peak efficiency of trays is at values of the vapor factor F = uρ in the range of 1.2–1.5 m/s

s

3 0.5

3 0.5

{kg/m } [1–1.2 ft/s {lb/ft } ]. This range of F establishes the diameter of the tower.

s

Roughly, linear velocities are 0.6 m/s (2 ft/sec) at moderate pressures, and 1.8 m/s (6 ft/sec) in

vacuum.

3. Pressure drop per tray is on the order of 7.6 cm (3 in) of water or 0.007 bar (0.1 psi).

4. Tray efficiencies for distillation of light hydrocarbons and aqueous solutions are 60–90%; for