Page 369 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 369

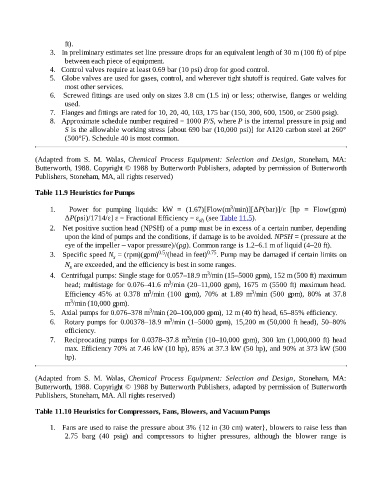

ft).

3. In preliminary estimates set line pressure drops for an equivalent length of 30 m (100 ft) of pipe

between each piece of equipment.

4. Control valves require at least 0.69 bar (10 psi) drop for good control.

5. Globe valves are used for gases, control, and wherever tight shutoff is required. Gate valves for

most other services.

6. Screwed fittings are used only on sizes 3.8 cm (1.5 in) or less; otherwise, flanges or welding

used.

7. Flanges and fittings are rated for 10, 20, 40, 103, 175 bar (150, 300, 600, 1500, or 2500 psig).

8. Approximate schedule number required = 1000 P/S, where P is the internal pressure in psig and

S is the allowable working stress [about 690 bar (10,000 psi)] for A120 carbon steel at 260°

(500°F). Schedule 40 is most common.

(Adapted from S. M. Walas, Chemical Process Equipment: Selection and Design, Stoneham, MA:

Butterworth, 1988. Copyright © 1988 by Butterworth Publishers, adapted by permission of Butterworth

Publishers, Stoneham, MA, all rights reserved)

Table 11.9 Heuristics for Pumps

3

1. Power for pumping liquids: kW = (1.67)[Flow(m /min)][ΔP(bar)]/ε [hp = Flow(gpm)

ΔP(psi)/1714/ε] ε = Fractional Efficiency = ε (see Table 11.5).

sh

2. Net positive suction head (NPSH) of a pump must be in excess of a certain number, depending

upon the kind of pumps and the conditions, if damage is to be avoided. NPSH = (pressure at the

eye of the impeller – vapor pressure)/(ρg). Common range is 1.2–6.1 m of liquid (4–20 ft).

0.5

3. Specific speed N = (rpm)(gpm) /(head in feet) 0.75 . Pump may be damaged if certain limits on

s

N are exceeded, and the efficiency is best in some ranges.

s

3

4. Centrifugal pumps: Single stage for 0.057–18.9 m /min (15–5000 gpm), 152 m (500 ft) maximum

3

head; multistage for 0.076–41.6 m /min (20–11,000 gpm), 1675 m (5500 ft) maximum head.

3

3

Efficiency 45% at 0.378 m /min (100 gpm), 70% at 1.89 m /min (500 gpm), 80% at 37.8

3

m /min (10,000 gpm).

3

5. Axial pumps for 0.076–378 m /min (20–100,000 gpm), 12 m (40 ft) head, 65–85% efficiency.

3

6. Rotary pumps for 0.00378–18.9 m /min (1–5000 gpm), 15,200 m (50,000 ft head), 50–80%

efficiency.

3

7. Reciprocating pumps for 0.0378–37.8 m /min (10–10,000 gpm), 300 km (1,000,000 ft) head

max. Efficiency 70% at 7.46 kW (10 hp), 85% at 37.3 kW (50 hp), and 90% at 373 kW (500

hp).

(Adapted from S. M. Walas, Chemical Process Equipment: Selection and Design, Stoneham, MA:

Butterworth, 1988. Copyright © 1988 by Butterworth Publishers, adapted by permission of Butterworth

Publishers, Stoneham, MA. All rights reserved)

Table 11.10 Heuristics for Compressors, Fans, Blowers, and Vacuum Pumps

1. Fans are used to raise the pressure about 3% {12 in (30 cm) water}, blowers to raise less than

2.75 barg (40 psig) and compressors to higher pressures, although the blower range is