Page 382 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 382

Next, the minimum number of simple separation units must be determined. Although there are single units

that produce multiple output streams (such as a petroleum refining pipe still with many side draws), most

units accept a single inlet stream and produce two outlet streams. For such simple separators, we need at

least (N–1) units, where N is the number of outlet streams (products, by-products, and waste). There are

two types of questions to answer concerning these units in the separation section: (1) What types of units

should be used? and (2) How should the units be sequenced?

12.3.1 General Guidelines for Choosing Separation Operations

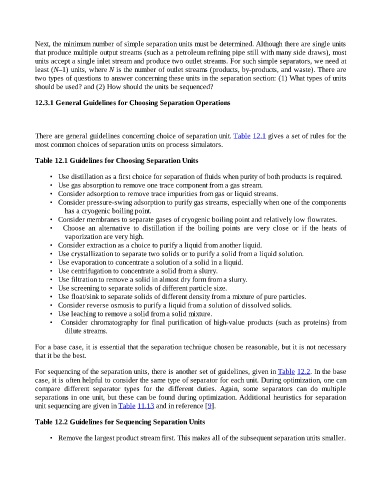

There are general guidelines concerning choice of separation unit. Table 12.1 gives a set of rules for the

most common choices of separation units on process simulators.

Table 12.1 Guidelines for Choosing Separation Units

• Use distillation as a first choice for separation of fluids when purity of both products is required.

• Use gas absorption to remove one trace component from a gas stream.

• Consider adsorption to remove trace impurities from gas or liquid streams.

• Consider pressure-swing adsorption to purify gas streams, especially when one of the components

has a cryogenic boiling point.

• Consider membranes to separate gases of cryogenic boiling point and relatively low flowrates.

• Choose an alternative to distillation if the boiling points are very close or if the heats of

vaporization are very high.

• Consider extraction as a choice to purify a liquid from another liquid.

• Use crystallization to separate two solids or to purify a solid from a liquid solution.

• Use evaporation to concentrate a solution of a solid in a liquid.

• Use centrifugation to concentrate a solid from a slurry.

• Use filtration to remove a solid in almost dry form from a slurry.

• Use screening to separate solids of different particle size.

• Use float/sink to separate solids of different density from a mixture of pure particles.

• Consider reverse osmosis to purify a liquid from a solution of dissolved solids.

• Use leaching to remove a solid from a solid mixture.

• Consider chromatography for final purification of high-value products (such as proteins) from

dilute streams.

For a base case, it is essential that the separation technique chosen be reasonable, but it is not necessary

that it be the best.

For sequencing of the separation units, there is another set of guidelines, given in Table 12.2. In the base

case, it is often helpful to consider the same type of separator for each unit. During optimization, one can

compare different separator types for the different duties. Again, some separators can do multiple

separations in one unit, but these can be found during optimization. Additional heuristics for separation

unit sequencing are given in Table 11.13 and in reference [9].

Table 12.2 Guidelines for Sequencing Separation Units

• Remove the largest product stream first. This makes all of the subsequent separation units smaller.